A “Shortcut” for Bladed Components

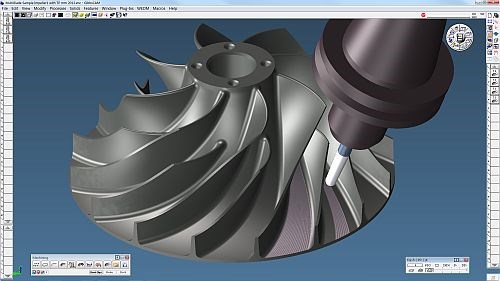

GibbsCAM offers two options designed to simplify the programming of bladed workpieces such as blisks and impellers.

Share

Industries like aerospace and automotive depend on bladed components such as impellers and blisks, but these workpieces can be complex and time-consuming to program and machine. ’ MultiBlade options for GibbsCAM provide a simplified user interface optimized for working with bladed workpieces within the GibbsCAM environment.

Two levels are available, depending on the type of work or level of specialization required. Level 1 covers workpieces with single splitters, and Level 2 can be added to support multiple splitters, sub-splitters, blade fillet machining and other advanced features.

Watch the video above, produced by Gibbs and Associates, for an overview of the MultiBlade functionality in GibbsCAM.

Related Content

-

How to Mitigate Chatter to Boost Machining Rates

There are usually better solutions to chatter than just reducing the feed rate. Through vibration analysis, the chatter problem can be solved, enabling much higher metal removal rates, better quality and longer tool life.

-

2 Secondary Coordinate Systems You Should Know

Coordinate systems tell a CNC machine where to position the cutting tool during the program’s execution for any purpose that requires the cutting tool to move.

-

ERP Provides Smooth Pathway to Data Security

With the CMMC data security standards looming, machine shops serving the defense industry can turn to ERP to keep business moving.

.jpg;width=70;height=70;mode=crop)