Aligned for Precision

To precisely condition the form, shape and finish of an inside diameter of a workpiece, no machine tool outperforms an ID grinder if (and only if) key components of this grinder are properly aligned. This article outlines the importance of this alignment, explains how to recognize the symptoms of misalignment and describes what corrective steps to take.

Share

To precisely condition the form, shape and finish of an inside diameter of a workpiece, no machine tool outperforms an ID grinder if (and only if) key components of this grinder are properly aligned. This article outlines the importance of this alignment, explains how to recognize the symptoms of misalignment and describes what corrective steps to take. The author, Bill Bednarski, is an applications engineer at Saint-Gobain Abrasives in Worcester, Massachusetts.

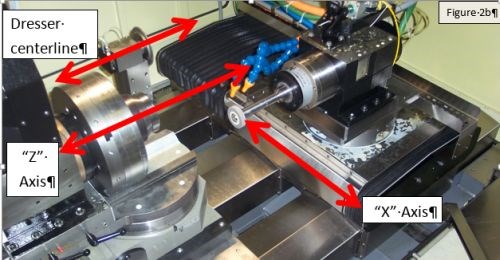

The components on a basic ID grinding machine that must always be in alignment are the X- and Z-axis slides, the grinding wheel spindle, the grinding wheel truing dressing device and the workhead spindle. As the linked article above shows, a properly aligned ID grinding machine, along with the right wheel specification and optimized grinding cycle parameters, will be a very cost-effective method to produce precision workpieces.

Related Content

-

Kaast Machine Tools' Solutions Enable Precise, Efficient Machining

IMTS 2024: Kaast Machine Tools Inc. is performing live demonstrations of several of its manufacturing solutions, including a vertical machining center, a cold saw and more.

-

Seeking Custom Grinding and Automation with Weldon Solutions

Weldon Solutions is demonstrating three grinders at IMTS 2024. Though they differ in size and use case, all feature the company’s hallmark customizations.

-

Chevalier Rotary Surface Grinders Provide Efficient Production

The FRG-400/600S Series is designed for heavy loads and is fully enclosed for CNC rotary surface grinding.