Alter the Axial Depth

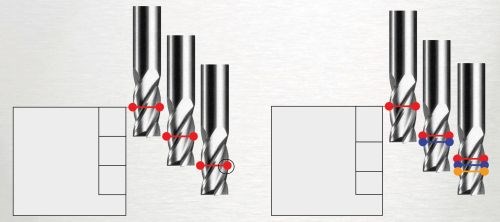

In difficult-to-machine metals, when a pocket or similar deep feature is milled in successively deeper Z-axis levels, oxidation and chemical reaction can affect the tool at the upper surface level of each cut. The solution: Change the axial depth of cut for each pass.

Share

In difficult-to-machine metals, when a pocket or similar deep feature is milled in successively deeper Z-axis levels, oxidation and chemical reaction can affect the tool at the upper surface level of each cut. Early damage to the tool can, therefore, occur at this one spot. The tool might have to be changed because of the wear at this one spot, even though the rest of the tool’s flute length is sharp.

The solution: Change the axial depth of cut for each pass. This will distribute the problem area to different points along the tool, as the drawing above suggests.

This practical advice is one of 10 tips for machining titanium recently provided by cutting tool supplier Stellram.

Related Content

-

Kyocera SGS End Mills Feature Seven-Flute Design

The H-Carb Series 77 end mills feature a specialized core and flute design to improve rigidity and chip flow while reducing deflection.

-

How to Mitigate Chatter to Boost Machining Rates

There are usually better solutions to chatter than just reducing the feed rate. Through vibration analysis, the chatter problem can be solved, enabling much higher metal removal rates, better quality and longer tool life.

-

Stability Maps for Milling

Selecting stable radial depths of cut for 2.5D milling.