An Insider’s Look at MTConnect-Enabled Applications

A new whitepaper from the MTConnect Institute is designed to help software developers create client applications that take advantage of the valuable data generated by manufacturing equipment but previously more difficult to access.

Share

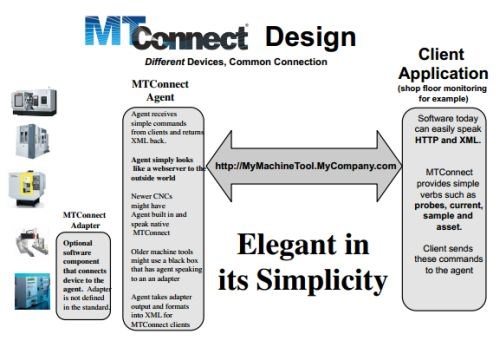

The whitepaper photo above depicts the Three As of MTConnect:

agents, adapters and applications.

MTConnect is an open and royalty-free standard for manufacturing that is connecting manufacturing equipment with applications by using proven Internet protocols. But MTConnect is not an application. Applications are software products designed to use data in the specified MTConnect format for such purposes as machine monitoring, energy usage management, cutting tool control and many others. A new whitepaper from the MTConnect Institute is designed to help software developers create applications that take advantage of the valuable data generated by manufacturing equipment that was more difficult to access before MTConnect appeared.

Although the content of this whitepaper is rather technical and thorough, it is readable and well-organized, so any shop interested in what MTConnect can do to improve operations ought to check it out for its insights into the inner workings of useful applications. The paper includes an overview of MTConnect, definitions of key terms, illustrations of essential concepts and basic outlines of application architecture. The whitepaper is available here.

Related Content

-

Blueprints to Chips: CAD/CAM Tips and Tricks

This collection of articles delves into the latest CAD/CAM innovations, from AI-driven automation and optimized tool paths to the impact of digital twins and system requirements.

-

Precision Shop Adopts Machine Monitoring, Boosts Revenue

Adopting machine monitoring helped LeClaire Manufacturing boost its vertical CNC utilization rates 38 percentage points and gain millions in revenue.

-

Manufacturer, Integrator, Software Developer: Wolfram Manufacturing is a Triple Threat

Wolfram Manufacturing showcased its new facility, which houses its machine shop along with space for its work as a provider of its own machine monitoring software and as an integrator for Caron Engineering.