Cell Automates Multiple Part Change-Overs

An automated work cell on display in Okuma’s Booth S-8500 demonstrates not only robots loading and unloading parts, but also automated production run change-overs.

Share

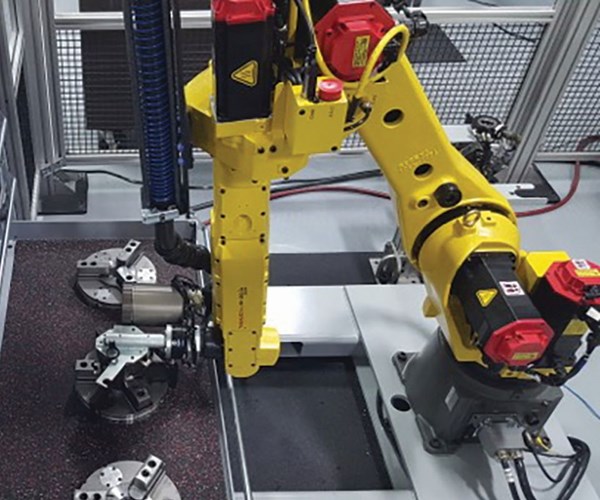

An automated work cell on display in Okuma’s Booth S-8500 demonstrates not only robots loading and unloading parts, but also automated production run change-overs. This means switching among a number of significantly different parts, not just members of a part family. In the cell, a Multus multitasking, CNC turning center performs a number of operations on a series of parts requiring three different three-jaw chuck face plates. A FANUC M-20iA industrial robot loads part blanks, unloads the finished parts and exchanges the chuck face plates as required.

Read the full story in the IMTS ​Show Daily.

Related Content

-

Cutting Part Programming Times Through AI

CAM Assist cuts repetition from part programming — early users say it cuts tribal knowledge and could be a useful tool for training new programmers.

-

Investing in Automation, Five-Axis to Increase Production Capacity

To meet an increase in demand, this shop invested heavily in automation solutions and five-axis machines to ramp up its production capabilities.

-

5 Stages of a Closed-Loop CNC Machining Cell

Controlling variability in a closed-loop manufacturing process requires inspection data collected before, during and immediately after machining — and a means to act on that data in real time. Here’s one system that accomplishes this.