Five Go-To Machining Technologies

There are a number of ancillary machine tool technologies that shops can use to become more efficient and effective. Here are five that I appreciate.

Share

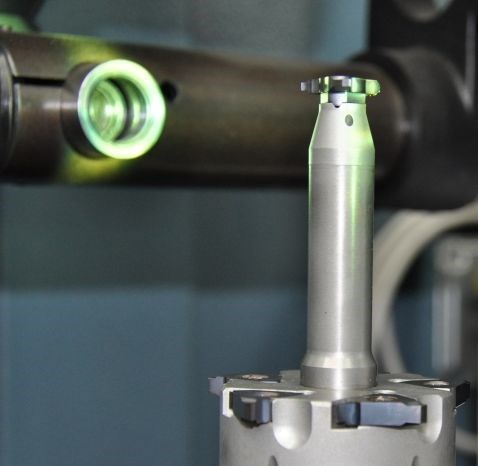

Toolholder assemblies for an upcoming job can be measured in seconds using a presetter, without the machine being interrupted.

We all know what opinions are like. That said, I thought of five pieces of ancillary machining equipment that I feel many shops can leverage to their success:

- Tool vending systems

- Tool presetters

- Machine tool probes

- High-pressure coolant delivery

- Shopfloor CMMs

Related Content

-

The Impact of Cutting Teeth Spacing on Machining Stability

Many cutter designs are available, and variable teeth spacing (or variable pitch) cutters can be used to influence milling stability. Let’s discuss why teeth spacing affects stability.

-

Finding the Right Tools for a Turning Shop

Xcelicut is a startup shop that has grown thanks to the right machines, cutting tools, grants and other resources.

-

Measuring Torque, Thrust Force for Smart Drilling Operations

To monitor drilling operations for smart manufacturing solutions, torque and thrust force can be measured.