Get the Handbook on MQL

A free handbook from Unist explains the benefits of minimum quantity lubrication and offers advice for those interested in moving away from conventional flood coolants.

Share

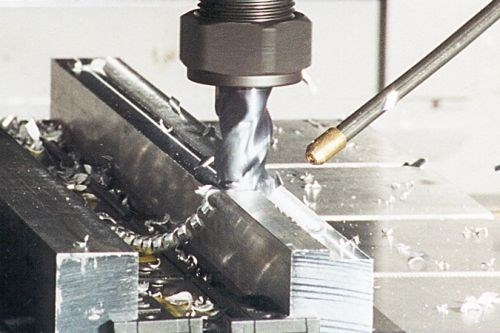

Minimum quantity lubrication (MQL) is used more in Europe than here in the States due to stricter environmental regulations across the pond. However, MQL has a proven track record in working just as well as, or better than, traditional flood coolants for certain applications. Plus, shops don’t have to deal with negative consequences like health hazards, disposal costs and pricey circulation equipment. If you’re interested in learning more about MQL, consider signing up to receive the “MQL Handbook” offered by , the Grand Rapids, Michigan manufacturer of MQL systems for metalworking applications.

The handbook explains how MQL differs from conventional coolant methods, how it works, what equipment is needed, how to develop an MQL process and what fluids work best for it. Sign up to receive the handbook .

Related Content

-

Oelheld Coolant Increases Metal Removal Rates

The odorless coolant is said to offer increased removal rates, lower electrode wear, excellent surface qualities, lower refill quantities and longevity to provide lower overall operating costs.

-

SpindleSHOT Offers Improved Chip Control and Less Maintenance

High-pressure coolant system is customizable to meet customer needs.

-

Hennig Inc. Acquires Industrial Coolant Systems

ICS develops and field tests high-pressure coolant systems, coolant filtration systems and other machine tool solutions.