IMTS: The Name Change Makes Even More Sense Today

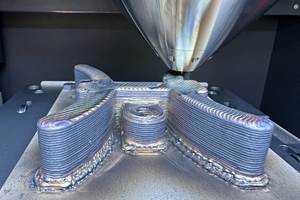

With the rapid expansion of additive manufacturing’s place at the show, the biennial event expands well beyond machine tools.

Share

Is an additive manufacturing machine a machine tool? Arguably not, and the organizers of IMTS decades ago seemed to anticipate that a technology such as this might one day be part of the show.

Back in 1990, the bienniel manufacturing event changed its name, choosing a new name that its initials could take in stride. What had been the International Machine Tool Show became the International Manufacturing Technology Show.

Nevertheless, IMTS has remained largely a machine tool show, with its biggest halls devoted to showcasing these machines. Most of the products exhibited—tooling, workholding, manufacturing software, measurement devices—are just one step removed from a machine tool. This year, however, will we see a significant departure from the show’s historical norm?

The answer depends on one’s answer to the question I started with: whether a machine for additive manufacturing (AM) is a machine tool. IMTS is still advancing as a major event for AM. The leading event in North America for manufacturing decision-makers, it is the right venue for companies supplying additive offerings. Accordingly, are exhibiting in the show’s Additive Manufacturing Pavilion this year compared to the last show—and that’s just the AM Pavilion. The number of machine tool builders and software companies showing additive-related solutions in the rest of the show has expanded as well. So is this technology just an incremental extension? Is additive a new and different machine tool variety?

The questions are important because the answers shape what one is able to see in the technology.

My answer is “sometimes yes,” in that a hybrid machine tool offering additive capability clearly is still a machine tool. Beyond that, my answer is “mostly no.” An additive manufacturing machine generating a complete part through AM is not a machine tool, because it does not do what a machine tool does. It does not fill the same niche. It changes the niche instead.

An AM machine can make a part that otherwise might have been machined. In that case, it takes the place of machine tool. But it can also consolidate connected parts into one piece. In that case, it takes the place of assembly. It can consolidate operations such as casting, machining and assembly into one step, taking the place of a supply chain and the shipping that links that chain. It can simplify the supply of aftermarket components, taking the place of a warehouse full of parts. It can open the way to entirely new possibilities in design, replacing design for manufacturability with design for functionality.

In short, additive touches so much of the process that it is less a manufacturing operation and more a manufacturing redefinition. It is less of a resource for the manufacturing department and more of a reshaping of the manufacturing enterprise.

There is more than this to say about additive. My observation here relates to IMTS. Manufacturing is changing, and AM is a significant part of the change. In pursuing and making a home for what is new in manufacturing, additive in particular, we see IMTS continuing to come into its own. We see the show living up to its name.

Related Content

How to Meet Aerospace’s Material Challenges and More at IMTS

Succeeding in aerospace manufacturing requires high-performing processes paired with high-performance machine tools. IMTS can help you find both.

Read MoreIn Moldmaking, Mantle Process Addresses Lead Time and Talent Pool

A new process delivered through what looks like a standard machining center promises to streamline machining of injection mold cores and cavities and even answer the declining availability of toolmakers.

Read MoreChuck Jaws Achieve 77% Weight Reduction Through 3D Printing

Alpha Precision Group (APG) has developed an innovative workholding design for faster spindle speeds through sinter-based additive manufacturing.

Read MorePush-Button DED System Aims for Machine Shop Workflow in Metal Additive Manufacturing

Meltio M600 metal 3D printer employs probing, quick-change workholding and wire material stock to permit production in coordination with CNC machines.

Read MoreRead Next

AMRs Are Moving Into Manufacturing: 4 Considerations for Implementation

AMRs can provide a flexible, easy-to-use automation platform so long as manufacturers choose a suitable task and prepare their facilities.

Read MoreLast Chance! 2025 Top Shops Benchmarking Survey Still Open Through April 30

Don’t miss out! 91ÊÓƵÍøÕ¾ÎÛ's Top Shops Benchmarking Survey is still open — but not for long. This is your last chance to a receive free, customized benchmarking report that includes actionable feedback across several shopfloor and business metrics.

Read MoreMachine Shop MBA

Making Chips and 91ÊÓƵÍøÕ¾ÎÛ are teaming up for a new podcast series called Machine Shop MBA—designed to help manufacturers measure their success against the industry’s best. Through the lens of the Top Shops benchmarking program, the series explores the KPIs that set high-performing shops apart, from machine utilization and first-pass yield to employee engagement and revenue per employee.

Read More