Inspection System Brings Programmability to Shopfloor Gaging

Gaging device extends the reach of the CMM out to the production floor, and provides an alternative to dedicated gaging.

Share

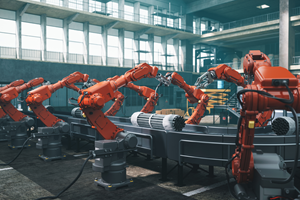

In the machining process for a complex and valuable production part, the workpiece is often removed from a flexible, programmable CNC machine tool, only to be inspected using a custom gage that is not flexible or programmable at all. “Hard” gaging—meaning measurement devices on the production floor designed and built for specific parts—provides a way to quickly inspect a workpiece near the machine. Yet hard gaging can also be costly. For jet engine component maker Meyer Tool in Cincinnati, Ohio, designing, building and maintaining a hard gage could cost $20,000, according to quality manager Beau Easton. If a design change to the part necessitates a change to the gage, then this could add thousands of dollars more.

Related Content

Increasing OEM Visibility to Shopfloor Operations for the Win

A former employee of General Motors and Tesla talks about the issues that led to shutdowns on factory lines, and what small- to medium-sized manufacturers can do today to win business from large OEMs.

Read MoreHorizontal High-Speed Machining Saves Hundreds of Work Hours

High-speed machining is the latest change at Blair-HSM South, helping this once old-fashioned shop improve productivity and morale while enabling new work.

Read MoreForkardt Hardinge Swiss Workholding Provides Reliable, Consistent Performance

The company’s Swiss collets are designed to securely hold parts without marring surfaces, minimizing vibration to ensure smoother machining, enhanced accuracy and extended tool life.

Read MoreAFRC, ATI Partner to Boost Aerospace Materials Innovation

ATI Inc. has joined the University of Strathclyde’s AFRC as a tier one member, aiming to develop metallic alloys that support sustainability in the aerospace sector.

Read MoreRead Next

Last Chance! 2025 Top Shops Benchmarking Survey Still Open Through April 30

Don’t miss out! 91ÊÓƵÍøÕ¾ÎÛ's Top Shops Benchmarking Survey is still open — but not for long. This is your last chance to a receive free, customized benchmarking report that includes actionable feedback across several shopfloor and business metrics.

Read MoreMachine Shop MBA

Making Chips and 91ÊÓƵÍøÕ¾ÎÛ are teaming up for a new podcast series called Machine Shop MBA—designed to help manufacturers measure their success against the industry’s best. Through the lens of the Top Shops benchmarking program, the series explores the KPIs that set high-performing shops apart, from machine utilization and first-pass yield to employee engagement and revenue per employee.

Read MoreAMRs Are Moving Into Manufacturing: 4 Considerations for Implementation

AMRs can provide a flexible, easy-to-use automation platform so long as manufacturers choose a suitable task and prepare their facilities.

Read More