Pairing Additive Mfr. and Topology Optimization for Diesel Engine Support Redesign

Topology optimization tends to increase geometric complexity. This isn't a challenge for additive manufacturing.

Share

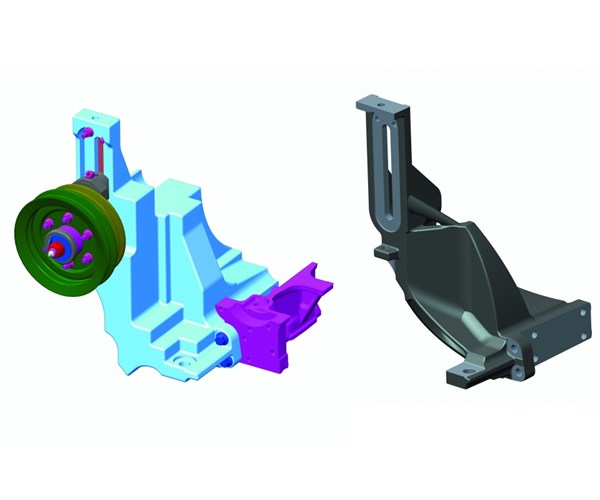

This diesel engine support is conventionally machined out of a solid block (left). Using topology optimization, researchers came up with a lighter version of the part (right) that could be produced via additive manufacturing.

Topology optimization aims to selectively place material in the locations required by a part's function, a process that tends to increase its geometric complexity. This fact makes topology optimization a natural pair with additive manufacturing, which is capable of building almost any such complex shape. Additive powder-bed processes such as selective laser melting (SLM) can create high-resolution, optimized features that would be difficult or impossible to machine. By the same token, topology optimization helps designers remove constraints and take better advantage of the design freedom additive manufacturing offers.

The diesel engine support pictured above is one example of a design made possible by the combination of additive manufacturing and topology optimization. Conventionally machined out of a metal block (left), the engine support connects the powertrain and chassis and supports a cooling system tensioner pulley. To optimize this part, researchers fed data about the support's load and other demands into a finite element model to come up with a lightweight, material-saving form (right) that would be difficult to achieve without additive manufacturing.

Learn more about the redesign process for this diesel engine support from Additive Manufacturing, sister publication to 91ÊÓƵÍøÕ¾ÎÛ.

Related Content

-

Push-Button DED System Aims for Machine Shop Workflow in Metal Additive Manufacturing

Meltio M600 metal 3D printer employs probing, quick-change workholding and wire material stock to permit production in coordination with CNC machines.

-

The Downloadable Metal 3D Printer

Copenhagen researchers introduce a fully open-source laser powder bed fusion system, now available on GitHub. This release follows their development of an open-source vat polymerization machine. Here is the purpose and promise of this philanthropically funded effort to advance additive manufacturing application and adoption.

-

The Cool Parts Showcase Seeks Innovative 3D Printed Parts

Do you solve problems with 3D printing? Enter your 3D printed parts in this contest from The Cool Parts Show.

.jpg;width=70;height=70;mode=crop)