Quickly Give Live Tools Coolant-Through Capability

This retrofit system enables users to quickly and easily add through-tool coolant delivery on their live tooling.

Share

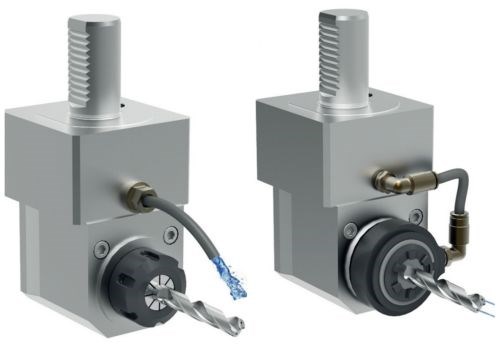

The Recool system from Rego-Fix enables users to quickly replace the conventional spray-pipe coolant delivery system on their live tooling (left) to through-tool coolant delivery (right).

Through-tool coolant delivery is more effective at getting coolant to a tool’s cutting edge than spray pipes or nozzles. Knowing this, Rego-Fix has developed a retrofit through-tool coolant delivery system for live tooling on CNC lathes that is said to install in minutes.

The animation demonstrates how simple it is to install this affordable system. Each Recool kit contains a special clamping nut with outer ring, a coolant pipe and a few fittings. The standard kit achieves maximum speed and pressure of 6,000 rpm and 300 psi, respectively, although higher speeds and coolant pressures are available upon request.

Related Content

-

Orthopedic Event Discusses Manufacturing Strategies

At the seminar, representatives from multiple companies discussed strategies for making orthopedic devices accurately and efficiently.

-

How to Troubleshoot Issues With Tool Life

Diagnosing when a tool is failing is important because it sets an expectation and a benchmark for improvements. Finding out why gives us a clue for how to fix it.

-

Quick-Change Tool Heads Reduce Setup on Swiss-Type Turning Centers

This new quick-change tooling system enables shops to get more production from their Swiss turning centers through reduced tool setup time and matches the performance of a solid tool.