Small Shop Achieves Logistical Autonomy with MES

A small laser shop depended on its parent company for invoicing while the shop manager had to juggle both orders and manufacturing. Workplan helped the shop become autonomous.

Share

AFDL, based in France, specializes in laser cutting of sheet metal in aluminum and steels. Recent growth in order volume has necessitated a move to a more robust shop management system.

Laser subcontractor AFDL operates with between five and eight employees at any given time. A small shop like this might not be the first context that comes to mind when it comes to the trends of Industry 4.0 and data-driven “smart production.” But implementing the Workplan manufacturing execution system (MES) in conjunction with Radan sheet metal CAD/CAM software — both systems from Hexagon Manufacturing Intelligence — enabled the company to achieve gains by moving into a more autonomous mode of operation.

Toward Logistical Autonomy

Focusing on laser cutting of 0.2- to 25-mm-thick sheet metal, French company AFDL has also developed its capabilities in bending and welding, producing stainless steel tables for the furniture industry and working for pharmacies and the public sector. After recent growth, the company now produces as many as 50 orders a day, comprising individual unit parts as well as large series.

Prior to installing Workplan, Stéphane Noailly managed everything from order entry to manufacturing. “We didn’t have production management software, and invoicing was managed by our parent group, Decofor, involving double entry of all our delivery notes,” Mr. Noailly says. “We needed to invest in this type of software because of strong growth and more employees. It was becoming too complicated to manage the company’s activities with Excel files.”

Having used Radan as its sheet metal production software for some 10 years, the company opted to adopt Workplan because it was from the same provider, Hexagon.

Since the installation and deployment of Workplan along with its Radquote module, Mr. Noailly has been able to free up time to develop the company’s operations. The shop has since become completely autonomous from Decofor in its job management, quotation and invoicing.

Radquote, a module of Workplan from Hexagon Manufacturing Intelligence, has helped AFDL become autonomous from its parent company, Decofor, which previously had to handle the shop’s invoicing.

The Manufacturing Execution System at Work

Since implementing the Workplan and Radquote system for automated time analysis, production cost estimation and quotation generation on its sheet metal parts and assemblies, AFDL has become more responsive, accurate and fair in its pricing, Mr. Noailly says. In 2013, AFDL was formed with Decofor as its only customer. Today, half of its customers are external. Mr. Noailly says that Workplan helped the shop thrive with this expansion in demand.

The software enables him to generate precise quotes and either duplicate or modify them for similar new orders. He can also transform quotes into orders, which he can then view in their totality. Delivery notes can be generated by entering the order number into the software, which Mr. Noailly says helps the shop avoid missing invoices.

“Recurring orders from Decofor are now managed with just a few clicks,” he says by way of example. “The file is sent in CSV format, and Workplan transforms it into a command. No more re-entries or errors. It’s a real time saver, as production starts immediately.”

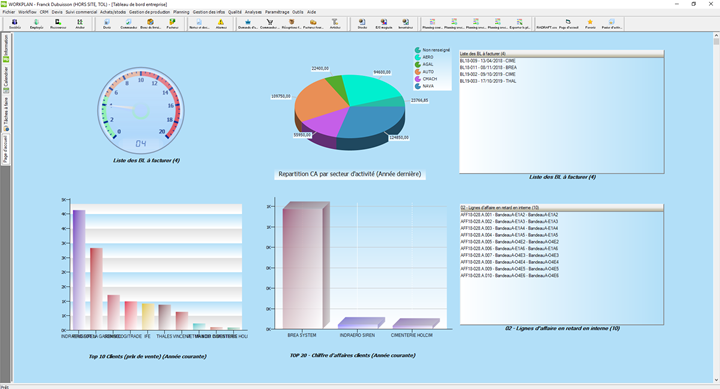

An example of a customized analysis page in Workplan. The software, specifically designed for job shops, is said to ease job quoting and management, status notification, purchasing and stock management, planning and scheduling, and more.

The Benefits of CAD/CAM Integration

AFDL’s success with Workplan is due in part to its integration with Radan. The shop originally began using the CAD/CAM software because it was already installed on a machine tool Decofor purchased at auction and which AFDL inherited.

Radan enables the shop to operate at 24-hour production, seven days per week. The software powers two Trumatic Laser 3050s along with an Amada HFT press brake. The shop is planning on replacing one of these in order to move into copper and brass cutting for the electrical sector.

“Thanks to Radan, we can produce up to 30 pieces on the same day that the order is placed, which means we can readily adapt to our customers’ urgent demands when they require something immediately,” Mr. Noailly says.

“We’re only a small company, but the integrated solution of Workplan and Radan has brought our factory in line with the Industry 4.0 philosophy of ‘smart production’ adopted by companies many times our size,” he concludes.

Related Content

Refining Shopfloor Processes for Mission-Critical Parts

Pacon Mfg, Inc. has not rested on its laurels as the 2020 Top Shop Honoree for Shopfloor Practices and Performance. In the years since, it has refined its processes to continue excelling in a volatile market.

Read MoreIncrease Savings and Streamline Purchasing Operations with Amazon Business

Machine shops and small manufacturers are finding cost and time savings using Amazon Business in their shops.

Read MoreAutomation and Process Simplification Define Eastec 2023

Manufacturing technology at this year’s Eastec met the market with tools to streamline operations and assist machinists in achieving greater productivity.

Read MoreERP and Process Changes Increase Shop’s Revenue 64% YoY

Implementing ProShop has led to a massive process overhaul at Marzilli Machine. From 2020 to 2021, revenue increased 64% without capital investment.

Read MoreRead Next

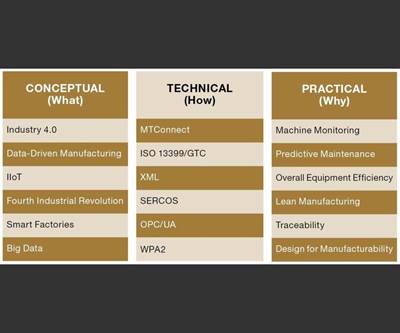

Data-Driven Manufacturing Deconstructed

"Data-Driven Manufacturing" can be broken into three areas for better understanding: the conceptual, the technical and the practical.

Read MoreMachine Shop MBA

Making Chips and 91ÊÓƵÍøÕ¾ÎÛ are teaming up for a new podcast series called Machine Shop MBA—designed to help manufacturers measure their success against the industry’s best. Through the lens of the Top Shops benchmarking program, the series explores the KPIs that set high-performing shops apart, from machine utilization and first-pass yield to employee engagement and revenue per employee.

Read MoreLast Chance! 2025 Top Shops Benchmarking Survey Still Open Through April 30

Don’t miss out! 91ÊÓƵÍøÕ¾ÎÛ's Top Shops Benchmarking Survey is still open — but not for long. This is your last chance to a receive free, customized benchmarking report that includes actionable feedback across several shopfloor and business metrics.

Read More