The Key to Repeatable 3D Printing? Materials

The latest issue of Additive Manufacturing Magazine explores how materials will be the key to production 3D printing.

Share

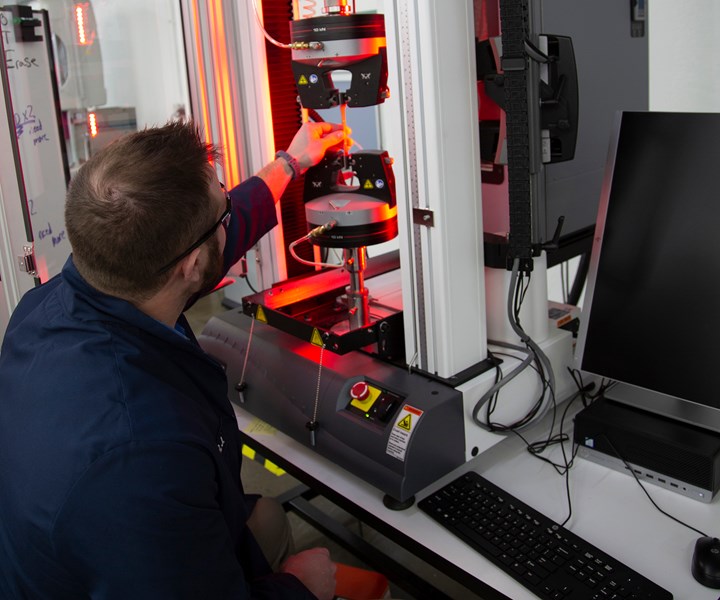

Developing, testing and manufacturing materials for 3D printing will be necessary to advance the technology into full-scale production.

Both 91ÊÓƵÍøÕ¾ÎÛ and sister publication Additive Manufacturing have covered plenty of examples where 3D printing is being used to manufacture real, end use parts. It is already being applied to manufacture , , milling tools, rockets and .

But what’s holding additive manufacturing (AM) back from its holy grail, full-scale production? One of the biggest hurdles to overcome is materials. Reliable materials, with proven print profiles, will be needed — in adequate quantities — if AM is to reach this next stage.

The September issue explores how via additive manufacturing.

The September/October issue of Additive Manufacturing Magazine details how various organizations who recognize this challenge are dealing with it. Stories in this issue include:

- Research by the National Institute for Aviation Research (NAIR) to build out a database of materials and process information for AM.

- How Jabil, one of the world’s largest contract manufacturers, is not only developing new 3D printing materials but working to ensure a reliable supply chain for mass production.

- Evidence that 3D printed polymer parts can outperform molded ones for a common requirement.

- A hybrid manufacturing strategy that combines an unusual material, topology optimization and interlayer laser peening.

- Recommendations for improving operator safety in the face of emissions from polymer 3D printing.

and to receive the next issue in your mailbox or inbox.

Want to learn more about 3D printing?

Sister publication explores how manufacturers are applying 3D printing to make tooling, molds, functional prototypes and end-use parts. .

Related Content

-

Digital Thread Enables First-Time-Right 3D Printing

Connecting all stages of manufacturing, from design to postprocessing, helps break down barriers to industrializing additive manufacturing.

-

Designing a 3D Printed Part with Machining in Mind

Designing extra stock and mounting features into a 3D printed part can aid in machining processes downstream.

-

6 Trends in Additive Manufacturing Technology

IMTS 2024 features a larger Additive Manufacturing Pavilion than ever before, with veteran suppliers alongside startups and newcomers at the front of the West Building. As you browse these exhibitors, as well as booths found elsewhere at the show, keep an eye out for these trends in AM.

.jpg;width=70;height=70;mode=crop)