Useful Advice for CAM Software Users

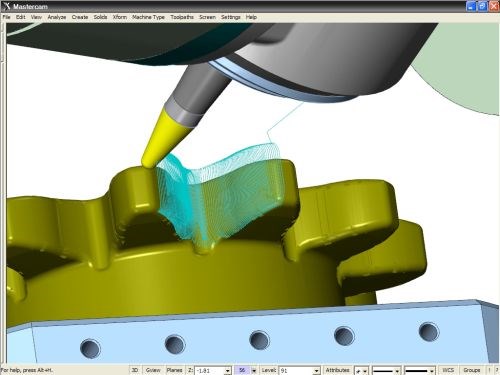

In a whitepaper, Mastercam calls useful advice for CAM software users “CAM Initiatives.” These initiatives are practical projects and procedural policies designed to help a machining company make more effective use of its CAD/CAM resources. Although primarily targeted to Mastercam users, many of these initiatives contain useful advice that benefits users of any CAM software system.

Share

In a new whitepaper, Mastercam calls useful advice for CAM software users “CAM Initiatives.” These initiatives are practical projects and procedural policies designed to help a machining company make more effective use of its CAD/CAM resources. Although primarily targeted to Mastercam users, many of these initiatives contain useful advice that benefits users of any CAM software system.

Here are a few samples:

- Say “no” to drawings. Don’t redraw parts until you are sure the customer does not have a usable CAD file to share. (They usually do.)

- Fix what isn't broken. Empower everyone in the shop to be an improvement specialist.

- Manage tool libraries. Find the cutting tools that work best in high-speed tool paths and use these tools exclusively where applicable.

- Embrace five-axis machining. Follow this launch plan to ensure a successful transition.

Other initiatives have advice on 3+2 machining, programming templates, spindle probes, simulation and integrating safety habits.

For the complete whitepaper with all 15 CAM Initiatives, click here.

Related Content

-

6 Machine Shop Essentials to Stay Competitive

If you want to streamline production and be competitive in the industry, you will need far more than a standard three-axis CNC mill or two-axis CNC lathe and a few measuring tools.

-

The Power of Practical Demonstrations and Projects

Practical work has served Bridgerland Technical College both in preparing its current students for manufacturing jobs and in appealing to new generations of potential machinists.

-

2 Secondary Coordinate Systems You Should Know

Coordinate systems tell a CNC machine where to position the cutting tool during the program’s execution for any purpose that requires the cutting tool to move.