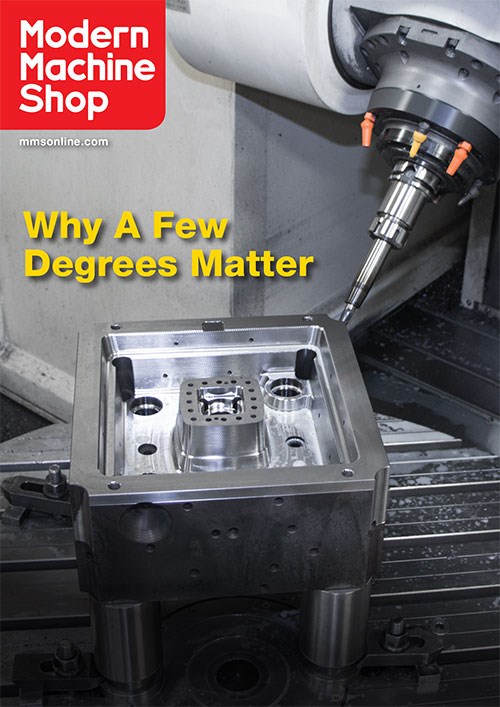

Why a Few Degrees Matter

3 + 2 machining might not be as captivating as five-axis contouring operations, but it can be just as valuable.

Share

Five-axis machines enable two types of multi-axis machining operations: full contouring and positioning (a.k.a. 3 + 2 machining). Thought of as siblings, contouring would be the alluring one and 3 + 2 would be more on the homely side. This is because contouring operations feature complex simultaneous motion of all five axes during a cut while 3 + 2 only uses the rotary axes to position and then lock the tool and/or workpiece at different angles outside of the cut.

That said, many shops find great value in 3 + 2. One is Canada’s . It now leverages 3 + 2 to manufacture more reliable and effective molds for thin-walled containers. Among other benefits, this capability has enabled it to reduce setups of mold inserts from as many as 25 to two, as detailed in this story.

Related Content

-

4 Rules for Running a Successful Machine Shop

Take time to optimize your shop’s structure to effectively meet demand while causing the least amount of stress in the shop.

-

How to Meet Aerospace’s Material Challenges and More at IMTS

Succeeding in aerospace manufacturing requires high-performing processes paired with high-performance machine tools. IMTS can help you find both.

-

How to Determine the Currently Active Work Offset Number

Determining the currently active work offset number is practical when the program zero point is changing between workpieces in a production run.