Workholding That’s on Point

A pin-based workholding system quickly accommodates workpieces of any shape.

Share

Did you or one of your kids ever play with one of those ? The idea was that you could press any object—a smaller toy or a hand, for instance—gently into the pins on the back of the board and see a crude relief image on the other side.

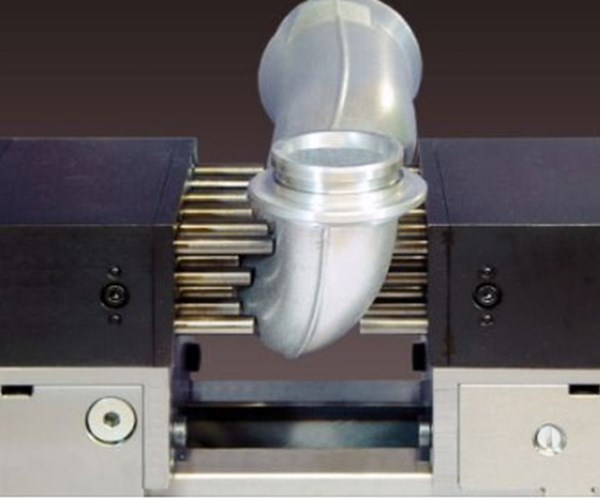

A clamping element from Euro-Tech called “The Jaw” (pictured above) works in a very similar fashion. The product has a number of hydraulic pins on each side that quickly conform to the shape of any part placed between them. Internal clamping sleeves lock the pins in place, and the company says that the form fit reduces required clamping force. The adaptable system can be used as jaws for vises, as supports, and in combination with robot grippers and other custom solutions.

Related Content

-

Chuck Jaws Achieve 77% Weight Reduction Through 3D Printing

Alpha Precision Group (APG) has developed an innovative workholding design for faster spindle speeds through sinter-based additive manufacturing.

-

Shop Reclaims 10,000 Square Feet with Inventory Management System

Intech Athens’ inventory management system, which includes vertical lift modules from Kardex Remstar and tool management software from ZOLLER, has saved the company time, space and money.

-

Custom Workholding Principles to Live By

Workholding solutions can take on infinite forms and all would be correct to some degree. Follow these tips to help optimize custom workholding solutions.

.jpg;width=70;height=70;mode=crop)