Why Are Holes Circular?

Geometries that are easy to machine may not be easy to fabricate additively.

Share

We begin this month’s column with that simple question: Why are holes circular? Is it because creating them that way makes for the most efficient use of material? Is it because that is how nature makes them? I think the answer is because that is how we are used to machining them. Drilling a hole is fastest and easiest when that hole is circular. This mindset is rooted in our conventional way of thinking about manufacturing—as a subtractive process that removes material from an existing block or piece of stock.

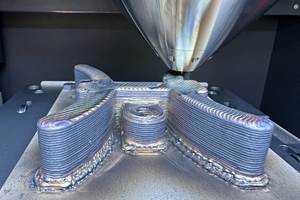

In additive manufacturing, making a circular hole actually can be quite difficult, depending on its size and orientation. This may be hard to believe, but it is true, especially when the hole runs perpendicular to the direction of the additive build, as shown in the first image in the above slideshow. Because in the additive process the part is built up layer by layer (shown in blue), the resulting geometry will show a “stair step” around the perimeter of the hole, and support structures (shown in yellow) will likely need to be created in order to support the overhang as the top of the circle is approached. Granted, this image over-emphasizes the thickness of the layers, but even at 20-60 microns (typical layer heights for current laser-based powder bed fusion systems), circular holes oriented perpendicular to the build direction are far from perfectly circular. Even holes that run parallel to the build direction can encounter issues of distortion and surface finish—but that is a discussion for another day.

So I ask again: Why are holes circular? In additive manufacturing, they do not necessarily need to be. In fact, they are easier to print when they are not circular. By easier, I mean that we do not have to add in support structures, which then need to be removed after fabrication. This is what made the automotive component in last month’s column so difficult and challenging to build. Namely, it required lots of circular holes and interfaces in order to connect the part to the wheel fasten to the suspension of the racecar. In that case, the holes had to be circular because of the mating interfaces. Eventually, though, additive manufacturing will help us reduce the number of mating interfaces needed, because we can design and fabricate multi-piece assembles as a single 3D-printed part (GE’s LEAP nozzle is the leading example of this right now).

For now, if you want to build a horizontal hole that mates to a circular part using AM, try using the support structures to your advantage. The second image above shows a great example of a design one of our design engineers and AM experts, Corey Dickman, came up with for a threaded interface.

The hole was large enough that it needed support structures inside, and the threads were small enough that they could not be printed. Corey quickly realized that the printed hole would need to be machined and tapped afterward to mate with the connector, so he designed a machining guide inside the support structure that would help align the part and tool for this machining. This design enhancement required minimal extra build time and material, yet it saved a fair bit of post-processing time while also giving the tool enough material to “bite” into when machining. Support structures are not usually fully dense and can cause problems during machining, however, and we will discuss this issue in a future column. In the meantime, think about why the holes you create are circular and whether they really need to be—or if that is just the easiest way to make them.

Related Content

Machine Tool Drawbar Made With Additive Manufacturing Saves DMG MORI 90% Lead Time and 67% CO2 Emission

A new production process for the multimetal drawbar replaces an outsourced plating step with directed energy deposition, performing this DED along with roughing, finishing and grinding on a single machine.

Read MorePush-Button DED System Aims for Machine Shop Workflow in Metal Additive Manufacturing

Meltio M600 metal 3D printer employs probing, quick-change workholding and wire material stock to permit production in coordination with CNC machines.

Read MoreAdditive/Subtractive Hybrid CNC Machine Tools Continue to Make Gains (Includes Video)

The hybrid machine tool is an idea that continues to advance. Two important developments of recent years expand the possibilities for this platform.

Read MoreThe Downloadable Metal 3D Printer

Copenhagen researchers introduce a fully open-source laser powder bed fusion system, now available on GitHub. This release follows their development of an open-source vat polymerization machine. Here is the purpose and promise of this philanthropically funded effort to advance additive manufacturing application and adoption.

Read MoreRead Next

Machine Shop MBA

Making Chips and 91ÊÓƵÍøÕ¾ÎÛ are teaming up for a new podcast series called Machine Shop MBA—designed to help manufacturers measure their success against the industry’s best. Through the lens of the Top Shops benchmarking program, the series explores the KPIs that set high-performing shops apart, from machine utilization and first-pass yield to employee engagement and revenue per employee.

Read MoreAMRs Are Moving Into Manufacturing: 4 Considerations for Implementation

AMRs can provide a flexible, easy-to-use automation platform so long as manufacturers choose a suitable task and prepare their facilities.

Read More