Collet Chuck Adapters Available from Exsys Automation

Company has added type 01 ER collet chuck standard adapters that enable quick change over in turning center turrets.

Share

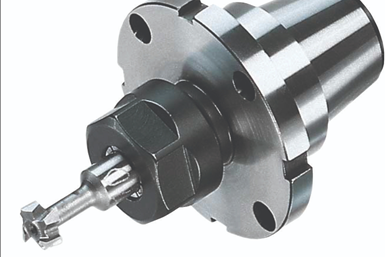

As part of its Preci-Flex modular tooling system, Exsys Automation Inc. offers the Type 01 ER Collet Chuck Standard Adapter. This precision-made tooling is designed to allow shops to change over tools in turning center turrets quickly, accurately and economically.

For machining close to the OD or ID of a workpiece, the Type 01 Adapter extends drills or end mills away from the face of the toolholder for additional reach. The adapters allow for offline tool presetting for the next job while the machine continues to work uninterrupted, according to Exsys.

The Type 01 Adapter features a “cap style” collet nut that is said to deliver increased clamping pressure that enables it to draw the collet into the adapter pocket for stronger holding power. The adapter can also shrink the collet pocket size without having to switch out holders.

Exsys Automation’s Preci-Flex is a tooling system with a single base holder and multiple tooling adapters. Its compact design is said to enable maximum torque transmission and rigidity, which the company says results in increased machining accuracy and improved productivity. According to Exsys, the modular system’s conical and flat face planar interface allows the use of either an adapter or a standard ER collet, and enables collets, end mill holders, expanding collet chucks and shrink fit tooling to be mounted on a single base holder.

Related Content

-

Lean Approach to Automated Machine Tending Delivers Quicker Paths to Success

Almost any shop can automate at least some of its production, even in low-volume, high-mix applications. The key to getting started is finding the simplest solutions that fit your requirements. It helps to work with an automation partner that understands your needs.

-

Chuck Jaws Achieve 77% Weight Reduction Through 3D Printing

Alpha Precision Group (APG) has developed an innovative workholding design for faster spindle speeds through sinter-based additive manufacturing.

-

How to Troubleshoot Issues With Tool Life

Diagnosing when a tool is failing is important because it sets an expectation and a benchmark for improvements. Finding out why gives us a clue for how to fix it.

.JPG;width=70;height=70;mode=crop)