DP Technology Optimizes ESPRIT for Willemin-Macodel

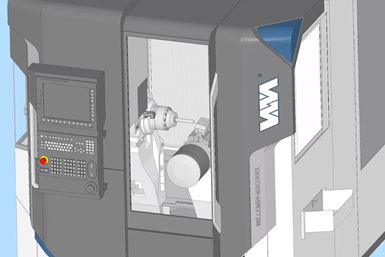

DP Technology has worked with Willemin-Macodel to optimize the ESPRIT CAM software for Willemin-Macodel’s complex mill-turn machines.

Share

Although the complexity and strict precision requirements for workpieces manufactured on Willemin-Macodel’s mill-turn machines made using traditional CAM software challenging, DP Technology worked directly with Willemin-Macodel to improve programming efficiency and user experience for Willemin-Macodel’s MT machines in DP Technology’s ESPRIT CAM software.

Benefits of this work include a simplified user interface for setting global machine settings, as well as capabilities for outputting machine-optimized, edit-free G-Code; creating and sorting operations in the required work coordinates; optimizing simulations to match the output NC code and actual machine behavior; displaying operation information to ease programming in ESPRIT; swift mounting of vise jaws on the turret and chucks and collets on the main and sub spindles; programming of tailstock and vise steady rest engage and disengage cycles; and flagging milling operations as cutoff operations.

DP engineers also worked closely with Willemin machine specialists to create a turn-key digital machine package consisting of post processors and virtual machines for the MT series. This package eliminates the time spent on editing the G-code and streamlines the machine setup and first article run off for end users.

DP Technology says ESPRIT provides not only a dedicated CAM solution for Willemin-Macodel machines, but also extensive engineering expertise and knowledge to make sure end users can start quickly and keep running at top efficiency using the MT series machines.

Related Content

-

Can ChatGPT Create Usable G-Code Programs?

Since its debut in late 2022, ChatGPT has been used in many situations, from writing stories to writing code, including G-code. But is it useful to shops? We asked a CAM expert for his thoughts.

-

Orthopedic Event Discusses Manufacturing Strategies

At the seminar, representatives from multiple companies discussed strategies for making orthopedic devices accurately and efficiently.

-

Setting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.