Hexagon VISI 2021 Improves CAD Analysis

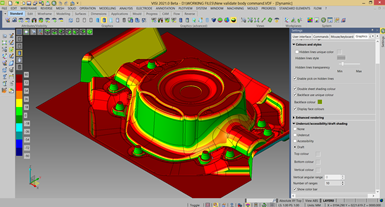

Hexagon's VISI 2021 includes new analysis-shading modes to improve CAD analysis.

Share

VISI 2021, the mold and die CAD/CAM software from Hexagon, includes new and enhanced functionality features, including new analysis-shading modes to improve CAD analysis. Draft Analysis joins the existing Undercut and Accessibility shadings, performing on-the-fly analysis of draft angles. This extends the undercut mode’s technique to more ranges, the company says. Users can change the colors and angular value of each range by clicking on the colors or numeric labels on the graphics toolbar.

Repair functions used in the Repair Invalid Faces of Bodies command are now integrated in the Validate command. Auto Zoom also enables users to zoom in on potential issues.

Developments to the CAD Reverse module are also said to improve the Reverse and Casting processes. The shaded view is designed to provide faster and more accurate feedback to the scanning operation, and new features increase the probing solution. “Leapfrog” management updates in Casting improve the laser tracker’s scanning accuracy for both small and large parts, according to the company. Reverse projects can now benefit from faster and more precise surface creation.

Point Scanning enables operators to view the shaded point cloud during the scanning operation, giving them an immediate report on scanning accuracy and potential missing areas.

A new option automatically creates a mesh as a scanning result, suitable for when results need to be quicker but not as detailed.

Improvements to probing during the Reverse process are designed to detect the correct diameter of the part in relation to the position of the probed points. A new Circle/Slot probing feature for probing and designing a circle or slot gives operators several options to ensure the probed element is the correct size and in the correct position. This prevents the need to create a mesh first, instead creating relative surfaces and saving time where curves can identify the shape.

Related Content

-

Tips for Designing CNC Programs That Help Operators

The way a G-code program is formatted directly affects the productivity of the CNC people who use them. Design CNC programs that make CNC setup people and operators’ jobs easier.

-

How this Job Shop Grew Capacity Without Expanding Footprint

This shop relies on digital solutions to grow their manufacturing business. With this approach, W.A. Pfeiffer has achieved seamless end-to-end connectivity, shorter lead times and increased throughput.

-

How to Mitigate Chatter to Boost Machining Rates

There are usually better solutions to chatter than just reducing the feed rate. Through vibration analysis, the chatter problem can be solved, enabling much higher metal removal rates, better quality and longer tool life.