Junker Develops All-in-One Grinding Machine

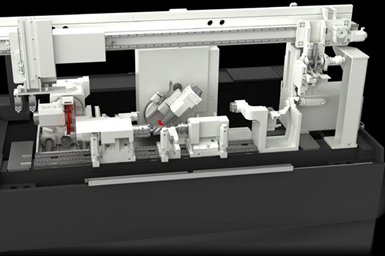

Junker’s Jumat 6L is capable of grinding high efficiency compressor shafts in one setup.

Share

Junker has developed a new technology that allows for the complete and precise grinding of screw compressor shafts. Junker’s rotor shaft machine, the Jumat 6L, is said to provide the capability to grind high efficiency compressor shafts in one setup, with part quality controlled by the grinding machine.

, a manufacturing company in Michigan City, Indiana that has been a Junker customer since 2011, has changed their finishing process with the Jumat 6L, eliminating the demand to pair shafts and achieving high compressor efficiency. In the past, the process required multiple grinding machine setups to finish a shaft. Diameters and faces of the shaft were ground on the Junker Quickpoint prior to grinding the compressor flutes on form grinding machines. Today, with the Jumat 6L, all of this is done in one setup and one machine.

The machine in process systems measure key features and automatically adjust the process without operator intervention. Junker developed the capability to measure the complex compressor flute profile and correct the dressing path to dress the CBN wheels automatically. Junker says this correction is essential, as tool pressure varies depending on the contact zone of the shape. It is necessary to apply a wheel with an incorrect shape to make a perfect part. The Junker machine produces parts with a total lead variation of ±3 μm and a profile accuracy of less than 6 μm.

The machine is equipped with a wheel changer for different flute shapes and for rough and finish grinding. The machine programs call up the correct wheels and monitor their life span. If a wheel has reached the end of its life, the controller requests a new wheel and alerts the production manager to purchase a new one. The parts are presented to the machine on a conveyor and loaded into the machine by an internal gantry system.

Related Content

-

CNC Machine Shop Honored for Automation, Machine Monitoring

From cobots to machine monitoring, this Top Shop honoree shows that machining technology is about more than the machine tool.

-

The Future of High Feed Milling in Modern Manufacturing

Achieve higher metal removal rates and enhanced predictability with ISCAR’s advanced high-feed milling tools — optimized for today’s competitive global market.

-

Quick-Change Tool Heads Reduce Setup on Swiss-Type Turning Centers

This new quick-change tooling system enables shops to get more production from their Swiss turning centers through reduced tool setup time and matches the performance of a solid tool.