Latest Siemens Parasolid Update Enhances Convergent Modeling

Siemens has updated its Parasolid software with enhanced convergent modeling functionality, also including substantial updates for boundary representation (B-rep).

Share

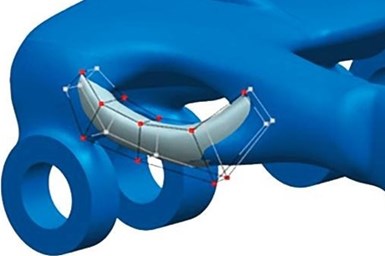

Siemens Digital Industries Software has updated Parasolid, its open software technology for geometric modeling. The latest release expands on convergent modeling for generative engineering, 3D-printing and reverse engineering applications, adding new tools that integrate previously incompatible facet and boundary representation (B-rep) data formats within a single modeling session. Siemens says this enhanced support for mixed models can help drive significant productivity gains by eliminating the need for time-consuming model conversion and allowing users to apply classic design techniques directly to facet models.

Parasolid’s update also allows it to add further value to design and engineering workflows in many different applications by allowing users to intersect meshes with all classic B-rep surface types and perform more sophisticated configurations of fillets and chamfers on mixed models. In addition, there are new tools for direct editing of faces and for rendering and repairing mixed models. The update also enhances B-rep in areas such as blending, sweeping, non-uniform scaling and rendering, bringing users gains in modeling flexibility and performance.

Siemens uses the Parasolid geometric modeling kernel in its own Solid Edge and NX software, and it serves as the core of the Xcelerator portfolio’s open and flexible ecosystem. The company also says Parasolid is used in over 350 other applications from industry-leading CAD/CAM/CAE/AEC software vendors.

Related Content

-

Chuck Jaws Achieve 77% Weight Reduction Through 3D Printing

Alpha Precision Group (APG) has developed an innovative workholding design for faster spindle speeds through sinter-based additive manufacturing.

-

The Downloadable Metal 3D Printer

Copenhagen researchers introduce a fully open-source laser powder bed fusion system, now available on GitHub. This release follows their development of an open-source vat polymerization machine. Here is the purpose and promise of this philanthropically funded effort to advance additive manufacturing application and adoption.

-

Digital Transparency in Machining Key to Multi-Site Additive Manufacturing

Cumberland Additive’s CNC programmer in Pennsylvania spends most of his time writing programs for machine tools in Texas.