NUMmonitor Software Enables Monitoring of Transfer and Multi-Process Machines

NUM’s NUMmonitor software is said to enable users of multi-process CNC machine tools such as transfer machines to implement process monitoring without incurring additional hardware costs.

Share

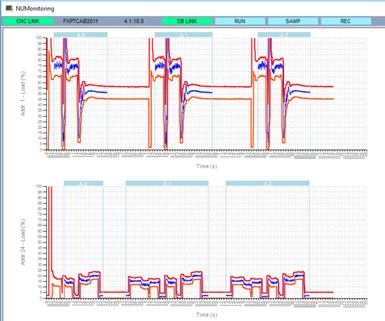

NUM’s NUMmonitor software is said to enable users of multi-process CNC machine tools such as transfer machines to implement process monitoring without incurring additional hardware costs. Through real-time monitoring of the power/current values of the electric motors on a transfer machine throughout its milling, turning or grinding processes, NUMmonitor minimizes downtime and maintains production quality by guarding against faults, the company says.

The software initially operates in “learn” mode to acquire the varying loads and drive currents of motors when the CNC machine tool is running at optimal performance levels and with a sharp new tool. Eight motors can be monitored simultaneously throughout the machine’s operating cycle, and the software accommodates up to 11 different error detection criteria per motor. In the case of multi-NCK systems, an additional eight motors can be monitored for each additional NCK.

Cycle-time related operating parameters determined from this process form “known good” event references which can then be used for comparison purposes against data sampled during subsequent production runs. User-programmed amplitude, duration and integral thresholds determine whether an event constitutes an “alert,” “alarm” or “shutdown” condition.

The new NUMmonitor software option can be installed and used on any Flexium+ CNC system running NUM’s Flexium software version 4.1.10.10 or higher. The Flexium+ includes a PC which can handle data from the servodrives’ measurement points, a programmable logic controller (PLC) with direct access to machine parameters and an NCK oscilloscope capable of reading values in real time. All system communications are handled by FXServer, using fast real-time Ethernet (RTE) networking.

Related Content

-

Can ChatGPT Create Usable G-Code Programs?

Since its debut in late 2022, ChatGPT has been used in many situations, from writing stories to writing code, including G-code. But is it useful to shops? We asked a CAM expert for his thoughts.

-

4 Commonly Misapplied CNC Features

Misapplication of these important CNC features will result in wasted time, wasted or duplicated effort and/or wasted material.

-

5 Tips for Running a Profitable Aerospace Shop

Aerospace machining is a demanding and competitive sector of manufacturing, but this shop demonstrates five ways to find aerospace success.