Red Lion Controls Expands SixTrak RTU Line

Red Lion Controls has added the ST-IPm-8460 to its SixTrak line of industrial RTUs. The company’s Red Lion Workbench software powers the device.

Share

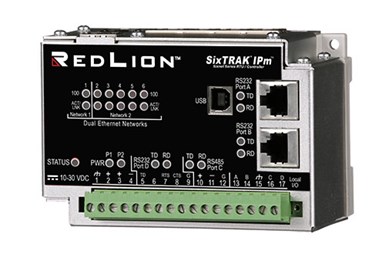

expands its SixTrak line of industrial remote terminal units (RTU) with the launch of the ST-IPm-8460, which operates on the Red Lion Workbench platform with an IEC61131-3-compliant editor and runtime engine. Red Lion says it designed the new RTU for applications that need increased processing and communication speed and storage, while maintaining the flexibility and reliability that customers require and expect from Red Lion to monitor and control equipment. The ST-IPm-8460 has achieved UL Class I, Div 2 certification and an ABS listing, while the construction supports operating temperatures from -40°C to 70°C, allowing the RTU to operate in harsh and hazardous locations.

The company says the combination of ST-IPm-8460 and Red Lion Workbench can support large, complex projects across multiple devices. Red Lion Workbench provides customized control, standard language support, debugging and monitoring tools, project automation and controller redundancy. The ST-IPm-8460, for its part, is available for configuration using Red Lion’s EtherTrak-2 I/O modules to scale its functionality to the user’s application.

Red Lion’s ST-IPm-8460 also offers private labeling as well as dual power inputs and support for redundant Ethernet networks to increase uptime, while a multitude of communication ports and supported protocols enable connectivity to a variety of field devices.

Related Content

-

Protecting Your Automation Investments

Shops need to look at their people, processes and technology to get the most of out their automation systems.

-

How this Job Shop Grew Capacity Without Expanding Footprint

This shop relies on digital solutions to grow their manufacturing business. With this approach, W.A. Pfeiffer has achieved seamless end-to-end connectivity, shorter lead times and increased throughput.

-

Leveraging Data to Drive Manufacturing Innovation

Global manufacturer Fictiv is rapidly expanding its use of data and artificial intelligence to help manufacturers wade through process variables and production strategies. With the release of a new AI platform for material selection, Fictive CEO Dave Evans talks about how the company is leveraging data to unlock creative problem solving for manufacturers.