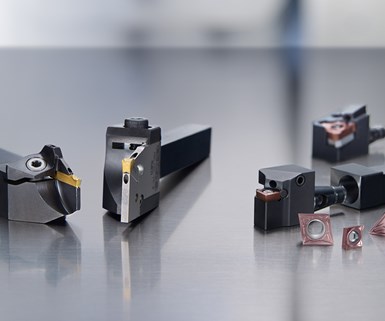

Seco's QC Toolholder Increases Swiss-Type Insert Indexing Efficiency

Seco’s modular QC (Quick-Change) toolholders for Swiss-type machining is designed to enable fast, easy and repeatable insert indexing and tool changes.

Share

Seco’s modular QC (Quick-Change) toolholders for Swiss-type machining are designed to enable fast, easy and repeatable insert indexing and tool changes outside of tight machine workspaces. For ease of use, the QC toolholder allows users to remove both cutting heads and inserts as a single assembly, then index and reinstall them. Manufacturers may also use this system to exchange cutting heads and inserts with a second set more efficiently. The cutting head also features double carbide pins for accurate, consistent and secure insert mounting and indexing.

The line includes cutting heads for general ISO turning, multi-directional turning (MDT), threading and parting off. Shanks are available in metric sizes of 10, 12 and 16 mm, and inch sizes of 0.375", 0.500" and 0.625".

The toolholders also feature Seco’s Jetstream Tooling and Jetstream Tooling Duo technology for chip control, surface finish quality and extended tool life. Jetstream Tooling directs high-pressure coolant through the QC Toolholder to the cutting zone. Jetstream Tooling Duo, available on a selection of cutting heads, adds a second coolant channel to the underside of the holder. The second coolant channel can be switched off if needed.

Related Content

-

Lean Approach to Automated Machine Tending Delivers Quicker Paths to Success

Almost any shop can automate at least some of its production, even in low-volume, high-mix applications. The key to getting started is finding the simplest solutions that fit your requirements. It helps to work with an automation partner that understands your needs.

-

High RPM Spindles: 5 Advantages for 5-axis CNC Machines

Explore five crucial ways equipping 5-axis CNC machines with Air Turbine Spindles® can achieve the speeds necessary to overcome manufacturing challenges.

-

Orthopedic Event Discusses Manufacturing Strategies

At the seminar, representatives from multiple companies discussed strategies for making orthopedic devices accurately and efficiently.