-

SPONSORED

-

SPONSORED

-

-

Articles

Where Does Diamond Make Sense In Machining Titanium?

Boeing machining experts say one application is drilling Ti-Composite stacks. PCD does well here. The group recently addressed this question submitted through our Aerospace Machining Zone.

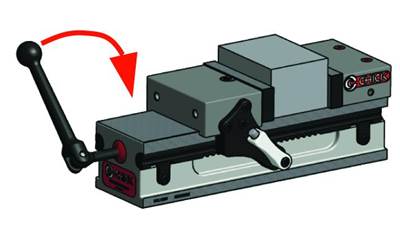

Read MoreA Vise Designed With CNC Machines In Mind

A sliding, locking mechanism allows users to quickly push this vise’s moveable jaw close to the workpiece before tightening the wrench. This minimizes the number of wrench turns to secure the part and allows users to quickly clamp parts of various sizes.

Read MoreThe High-Pressure Vise: An Alternative To Cheating

High-pressure vises are able to safely generate a significant amount of clamping force without machine operators resorting to using hammers or “cheater bars.”

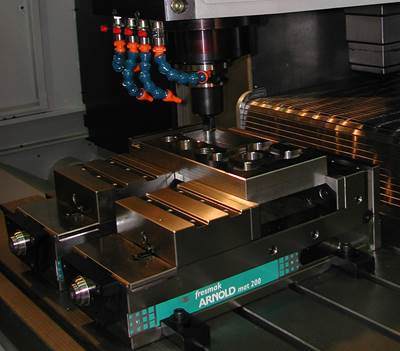

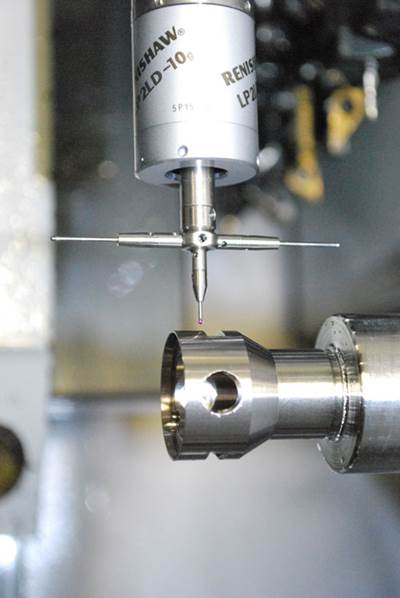

Read MoreProbing Beyond Prismatic

This manufacturer has used on-machine probing to help automate setups and maintain process control for prismatic parts produced on VMCs for years. The metrology products maker recently implemented probing strategies that let it achieve similar results on its turn-mills and Swiss-types. The smaller, more economical batch sizes these machines now produce are better aligned with true production requirements.

Read MoreGetting Credit Where Credit Is Due

Although current economic climate is by no means conducive to securing a lease or loan for a new machine or other equipment, shops with the right plan in place can still obtain the financing they need. One expert offers some advice for manufacturers seeking to obtain equipment financing amid the downturn.

Read MoreRigidity Required When Grinding Challenging Materials

Effective centerless grinding of hard materials requires a machine that is capable of damping process vibration at high wheel speeds and providing the rigidity to withstand very high cutting forces.

Read MoreSpindle Repair Simplified

This machine tool manufacturer's modular spindle design allows spindle repairs due to impact or contamination to be performed quick and easy.

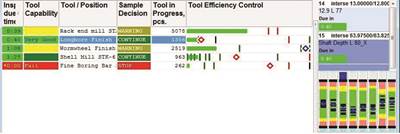

Read MoreThe Case For Integrated Control Of Machining Operations

An integrated software system automates a decision-making process that helps a machinist inspect parts on a timely basis, offset or change tools and appeal to engineers for improvement of process design.Â

Read MoreTaking CNC To The Next Level On A Multi-Spindle

A new generation of multi-spindle automatic lathes from the Czech Republic may change the thinking about the best way to produce complex parts in small to medium volumes. An innovative drive system on these machines enables users to optimize spindle speeds for specific machining operations.

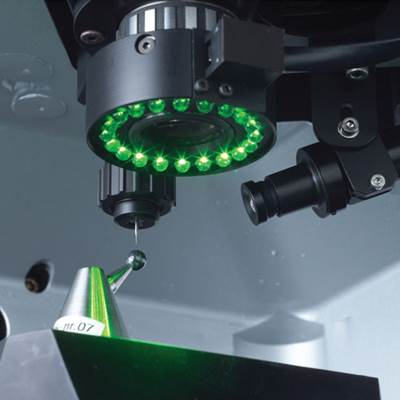

Read MoreMulti-Sensor CMM Eases Micro-Measuring

By combining an optical sensor and a touch probe, the F25 CMM from Carl Zeiss enables users to use the same machine platform to perform metrology operations on a variety of miniature parts.

Read MoreCompact Gaging System Allows In-Process Inspection On Small Grinding Machines

This new gaging system not only is compact enough to install on small grinding machines, but also can measure a part’s OD, ID and length to sub-micron accuracy.

Read MoreLaser On Multi-Sensor Inspection Systems Works In Deep Slots

A new laser system gives multi-sensor measurement equipment more flexibility. This system improves the equipment's ability to measure deep recesses and features with high walls.

Read More