-

SPONSORED

-

-

Articles

Alternate Tool Material For Hogging Large Workpieces

Shops often use either carbide or high speed steel cutting tools for hogging out the large workpieces common to the aerospace and moldmaking industries. While both materials have their advantages and disadvantages, cutting tool manufacturer Precision Cutting Tools says powder metal combines the best features of both. Â

Read MoreConsider Swiss-Types For Medical Opportunities

Adopting the latest machining technologies is key for shops to accurately and repeatably create medical components. Swiss-style lathes offer a good combination of precision and repeatability for these applications thanks in part to their guide-bushing design, which provides support for the workpieces very close to the cut.

Read MoreIf You Prototype It, They Will Come

For an upcoming article, I recently visited Protofab in Petaluma, California. I wanted to learn how this small job shop got into micro-machining medical implants. It turns out the shop didn’t win this work because it had the right equipment or because it was knowledgeable about machining tiny parts. The equipment a

Read MoreMaking Your Shop Eco-Friendly

A recent of MMS Extra issue asked how shops feel about environmentally conscious machining and carbon-footprint reduction. Dan Goldsmith at Elmira Stamping & Mfg. in Elmira, New York, ( www.elmirastamping.com ) responded by mentioning some of the practical steps that have been taken at his shop to reduce its e

Read MoreQuoting On Cool

To a job shop, bidding on an unusual job with a quote that is too high or too low is an occupational hazard. Bid too high and you won’t get the work. Bid too low and you will lose money. Perhaps the worst scenario is to submit a bid that you thought was too high, only to get the job anyway. When that happens, the s

Read MoreCheck Machine Details Before Delivery To Your Shop

When I am interested in writing about a new type of machine tool, I like to visit a shop or plant that has a representative model in place. Getting this user’s perspective is more objective and more relevant than just picking up info from other proponents. Writing the article is more fun, too. So typically, I talk

Read MoreIf The Shoe Fits

Trouble with our feet can be trouble, indeed. Foot problems can make our whole bodies ache. In many cases, if left untreated, these problems can be disabling. James A. Ryan, a doctor of chiropody in Toronto, Ontario, has devoted his professional career to helping people overcome foot problems. Chiropody is the medi

Read MoreMTConnect Moves Ahead

MTConnect is a machine tool communication standard being developed by AMT—The Association For Manufacturing Technology ( www.amtonline.org ). It’s reaching a critical point in its progress. It will soon need some “early adopters” who will embrace the concept, apply it to their products, champion the cause to other

Read MoreSpinning Turning Tool Offers Alternative To Single-Point Cutters

CAM developer DP Technology recently performed a successful test cut of a new cutting tool for turning applications that is designed to reduce vibration and heat buildup. The company's CAM software package, Esprit, now contains an add-on for programming the new tool. Developed jointly by machine tool builder Mori

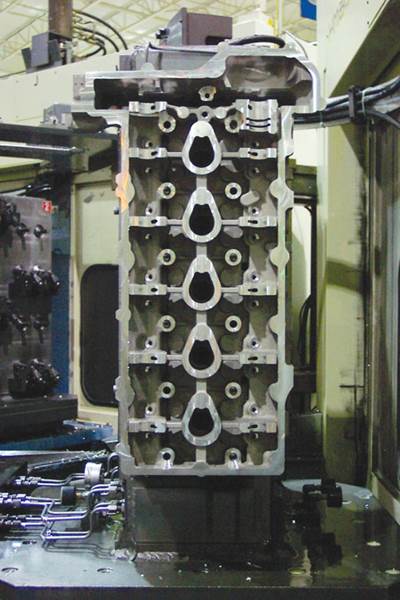

Read MoreHydraulic Workholding Devices Allow Total-Perimeter Machining

Having access to the entire perimeter of a part minimizes set ups because shops can machine five sides of the part in one fixturing. This enables shops to reduce the total number of manufacturing operations, the number of times parts must be handled, the potential for part damage due to excessive handling and the o

Read MoreElectrical Discharge Saw Slices Through Hard Alloys

Electrical discharge sawing uses spark-erosion technology and is said to create blanks from exotic alloys as much as 70 percent faster than wire EDM.

Read MoreClean Fire Suppression Protects Machines, Workers

Machine tool fires can cause unscheduled downtime, or worse, damage to the machine itself and possibly a shop’s facility. In fact, Siemens Building Technologies (Buffalo Grove, Illinois) says that more than 10 percent of all machine tools using non-hydrous coolants will have a fire incident within five years after installation.Â

Read More