Articles

Get Better Before You Get Bigger

Rather than making a major new machine tool purchase just yet, this shop is finding additional capacity on the equipment it already has. What once was a vertical machining center will become a flexible automated production center for unattended machining.

Read MoreMultitasking With A Small Footprint

The Integrex i-150 shows how a multitasking machine for small precision parts can combine done-in-one process with a compact structure to reduce floor space requirements. Most multitasking machines for parts of this size use a second spindle for endworking of parts after cutoff. This machine uses a swing-away workholding device instead.

Read MoreSmoothing Insert Surfaces Extends Tool Life

A post-coating finishing process smoothes any cracks in the outer coating of a cutting tool insert that develop during CVD and also removes droplets that PVD might leave behind. The resulting reduction in friction, heat and surface stresses is said to extend tool life and cutting performance.

Read MoreLarge Wire EDM Unit Gives Shop Room to Grow

This wire EDM job shop in Wisconsin acquired a submerged cutting wire machine that lets it handle larger, taller workpieces than just about any other job shop in the country. The new machine has a “column-up” option that adds a riser block between the X-axis saddle and the Z-axis column casting to give it exceptionally tall cutting capacity. The machine was installed in November 2007.

Read MoreIt Begins With Belief

This shop’s approach to unattended machining focuses on the big picture.

Read MoreContinuous Turning On Turn-Mills

A new CAM feature continuously manages B-axis head rotation to allow turn-mills to completely turn inner and outer workpiece profiles using a single tool.

Read MoreSynthetic-Diamond Dressing Tools: Why Not Use Them?

Synthetic-diamond dressing tools are often a superior alternative to natural-diamond dressing tools for conditioning a grinding wheel. The reason is the consistency that the synthetic-diamond tools bring to the process.

Read MoreRemote CNC Access And Operation

An all-hardware interface grants real-time access to CNC functions via the Internet without taxing the machine's brainpower.

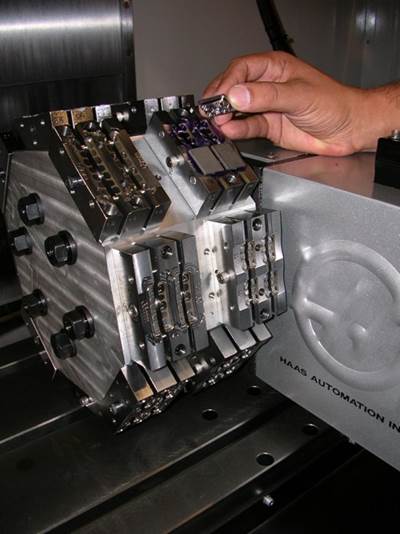

Read MoreAutomated Production Of Oil-Drill Couplings

A machining cell combines lathes, a robot and a conveyor system to enable automated production of precision oil-drill couplings.

Read MoreA Productivity Double-Take

As revealed at EMO 2007, DMG’s line of machine tools has a new look which strengthens the corporate identity of the product line while giving each brand distinctive design elements that differentiate it. The look is part of a “New Design” concept that the company says is based on the interaction among functionality, ergonomics and form. Significantly, a number of elements in the new design reflect attention to the role of the operator, thus indicating that the operator’s role is very important in overall machine tool productivity.

Read MoreHigh Speed Machining ... Without The Speed

Axial chip thinning is often associated with high speed machining, but this shop uses the same effect to increase metal removal rate with a standard-size end mill run on a moderate-speed machine.

Read MoreThe Case For Hydrostatic Ways

Moving on oil can let a grinding machine deliver more power along a smoother pass.

Read More