Articles

Turning Center With Ample Tool Positions

This multi-axis machine extends beyond the capabilities of a turning center, offering the tooling capacity similar to that of a machining center. As a result, it enables efficient machining of complex-shaped workpieces in large quantities.

Read MoreA Practical Guide To Presetters

Tool measurement devices help shops save time, control runout and improve tool management.

Read MoreRobots Make A Clean Sweep

A plant already effective at using robots for work handling applies robots to the end of the process as well, using them to clean and deburr intricate parts.

Read MoreWhen To Use A Spindle Chiller

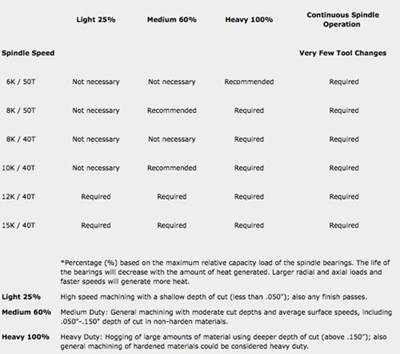

Because conventional spindles on machining centers are typically designed with a fixed bearing preload (no springs), there isn’t any compensation for the thermal expansion that occurs from heat generation. Higher temperatures cause the bearing raceways to expand and tighten. This causes the bearing system to increase its preload beyond the original setting, which leads to increased axial and radial loading on the bearing system.

Read MoreFinding The Right Words And The Right Process

This greeting card giant leverages hand-engraving competencies, digital media and high speed machining to produce press-ready dies so its cards are ready for the consumer's viewing pleasure.

Read MoreDesktop 3D Scanner Captures Part Shapes

This desktop laser scanning system allows 3D objects to be digitized so that the data can be used to create part geometry for tool path generation. The system's ease of use and low cost make reverse engineering available to machine shops that could not previously access this technology.

Read MoreGet A (Tight) Grip

High toolholder gripping torque reduces the likelihood that a tool will slip within a toolholder during a cutting operation. A mechanical toolholder design provides a very high gripping torque via a worm gear that compresses a shallow-taper collet tightly around a tool shank.

Read MoreProgram Prove-Out Via Machine Simulation

Before new machining jobs are run at this aerospace composites facility, they are first proven out using 3D machine tool simulation software. Such preventive measures have proven valuable in eliminating damage to tools, machines and parts.

Read MoreA Machine Designed With Contract Shops In Mind

This five-axis, moving-column machine features a table configuration allows C-axis rotation of small- to medium-sized parts as well as fixturing of very long workpieces.

Read MoreThe Appeal Of Peel Milling

Milling with high axial depth of cut and low radial depth of cut can offer an effective way to achieve high metal-removal rates in difficult materials.

Read MoreTaking The Plunge

It doesn't take sophisticated technology to perform plunge roughing effectively. In fact, if you are making due with a less effective machine, plunge roughing deserves even more serious consideration. (Includes video.)

Read MoreSuccessfully Feeding The Medical Market

This medical shop has adopted five-axis, bar-fed machining technology to adapt to compressed delivery schedules and increasingly complex part geometries.

Read More