-

SPONSORED

-

SPONSORED

-

-

Articles

Securing The Future

Multiple-part fixturing helps boost the output of these high-volume machining cells while preserving flexibility. The success of these cells is proving to be a critical component of this automotive part maker’s turnaround strategy.

Read MoreJust Enough Automation

Automated gantry loaders helped this shop make the transition from job shop to product line manufacturer.

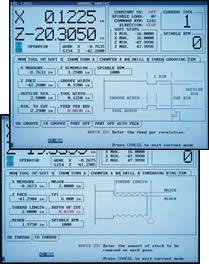

Read MoreThe Toolroom Lathe As An Alternative To CAM

The basic CNC lathe is not just for those who are new to NC. The ability to quickly program a job at the control can provide a quick alternative to programming off line.

Read MoreA Cool Deburring Technique

Ice blasting is a process that uses ice crystals as impact media to remove contaminants. It is popular in Europe for industrial cleaning work because it uses no detergents, solvents or abrasives.

Read MoreNew Lasers Are Mainstreaming Micro-Machining

Technical demands from the electronic, medical, aerospace and other industries are pushing the boundaries of micro-machining to smaller and more precise tolerances. The application of laser technology is pacing the demands from industry for smaller geometries and increasingly tighter specifications.

Read MoreUpgrading Machine Tools During A Market Uptick

These guidelines aim to help shops determine whether it is in their best interests to revive existing metalcutting equipment or to buy new machines.

Read MoreSlashing Programming Time For Similar Parts

There’s no reinventing the wheel for this shop! It saves machining programs in a knowledge base for use on future jobs.

Read MoreThe Process Before The Program

CAM automation can change the very focus of the programmer’s attention. Reduced programming time is only one of the benefits.

Read MoreSetup Reduction Is Central to Lean Manufacturing

This shop cut average setup time nearly in half. Now small batches can move quickly through the production process, making the company more responsive to customer needs than ever before.

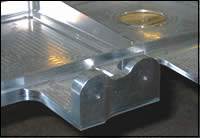

Read MoreSingle-Spindle Productivity

High speed, five-axis machining on single-spindle machine tools helps this aerospace shop meet the demand for rapid, single-piece work flow.

Read MoreTaking No Chances With Quality

A shop's good reputation is hard to build and easy to loose. Consistent quality is key to keeping customers. In its 30-plus year history, this Chicago specialty grinding job shop has never taken quality for granted.

Read MoreCenter Of Gravity Is Key To Reduced Vibration

The metalworking industry's keen interest in high speed, high accuracy machining during the last decade has focused attention on one topic in particular - vibration.

Read More