Measurement Vs. Experience in Optimal Machining Parameters

When it comes to finding chatter-free cutting speeds, measurement is the faster way to go. An anecdote illustrates this.

Share

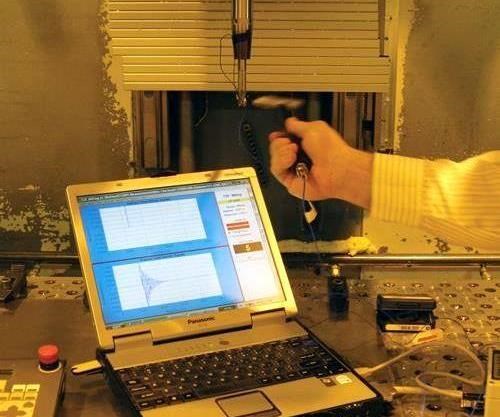

Relatively few shops perform frequency response measurements (like the one shown in the photo) to determine the optimal, chatter-free spindle speeds and depths of cut for their machines.

However, a much larger share of shops do run at something like these optimal parameters, because they eventually arrive at these parameters through the trial-and-error process of adjusting a machine’s speed until the chatter stops, and then cutting as deep as they can at that speed. The difference is: Measuring to find these parameters can get the shop to the optimal process faster, without so many parts being cut inefficiently along the way.

Jerry Halley of Tech Manufacturing experienced this. He was looking for a machining center that would perform well in heavy cutting of aluminum using a ¾-inch or 1-inch tool. For each of the machine models he considered, he went to where that machine was in use so he could measure to find the machine’s chatter-free milling speeds with these tools. (That measurement is often called a “tap test.”) A machine from SNK gave him the best performance he measured with the tools he wanted to use.

He shared this information with the machine’s user, the shop he was visiting to measure the machine. That is, he told team members at this shop the exact spindle speed at which they could run the machine to get the best efficiency with a 1-inch tool.

They said, essentially, “That sounds right.” The staff here had already figured out that this particular speed was best.

Mr. Halley nevertheless says there is an important point here that illustrates the value of the frequency response evaluation. In questioning the staff members further, he learned that they had fine-tuned the machine’s cutting parameters over the course of several months before coming to the correct findings that they did. By contrast, he came to the same correct conclusion with a measurement that took 15 minutes. Measurement and experience arrived at the same place, but measurement made it there much more quickly.

Learn more about measuring machine tools to find chatter-free cutting conditions here and here.

Read about Mr. Halley’s shop here.

Related Content

-

Lean Approach to Automated Machine Tending Delivers Quicker Paths to Success

Almost any shop can automate at least some of its production, even in low-volume, high-mix applications. The key to getting started is finding the simplest solutions that fit your requirements. It helps to work with an automation partner that understands your needs.

-

How to Troubleshoot Issues With Tool Life

Diagnosing when a tool is failing is important because it sets an expectation and a benchmark for improvements. Finding out why gives us a clue for how to fix it.

-

Shoulder Milling Cuts Racing Part's Cycle Time By Over 50%

Pairing a shoulder mill with a five-axis machine has cut costs and cycle times for one of TTI Machine’s parts, enabling it to support a niche racing community.