-

SPONSORED

-

SPONSORED

MMS Blog

Rough Faster With Better Tool Life in Difficult Materials

Optimized roughing, also called high-efficiency milling, is an effective way to improve material removal rates and tool life for titanium and hard-to-machine alloys, but knowing when to use it is as important as knowing how.

WatchLarge Equipment Offerings Buoyed by New CNC

To complement the strengths of many of its larger machine tools, Tarus has added a Heidenhain CNC to benefit those manufacturers seeking high-quality contour surface milling capabilities.

Read More4 CNC Data Transfer Methods You Should Know

Modern CNCs enable transfer and backup of more than just machining programs.

Read MoreAn Unusual Machine for an Unusual Time: Mazak Helps AquiSense Fight COVID-19 with PearlSurface

When a company that specializes in rendering viruses and pathogens harmless via UV light looked to produce a portable disinfection device, it turned to its neighbor Mazak to move from design into production.

WatchHigh-Torque Retention Knobs Solve Aerospace Milling Production Challenge

L.H. Thomson exclusively uses high-torque retention knobs from JM Performance Products on every tool on its machines to improve heavy milling on titanium and stainless steel parts.

Read MoreUse Your Machinists to Make Dies

By systemizing die making into repeatable steps, Dies Plus, a division of Otto Engineering, is using its machinists to effectively make dies. This solution relies on a paperless color-coding system to convey the tolerances machinists need to hit in order for tool and die makers to do the final fitting.

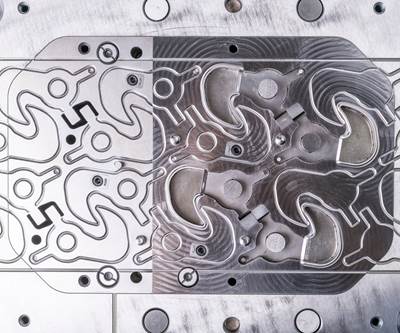

Read MoreHard Milling Replaces Hand Grinding in Finishing Die Components

A focus on repeatability, geometric capabilities and speed led this manufacturer of fine-blanking machines and components to embrace hard milling as its go-to finishing process, eliminating hand grinding.

Read MoreDeciding to Specialize as an Aerospace Supplier

Formerly a job shop serving a diverse local customer base, IPG responded to industry changes by transitioning into becoming an aerospace supplier. Here are the steps the shop is taking to make that change, including adding equipment and implementing plans for quality and marketing.

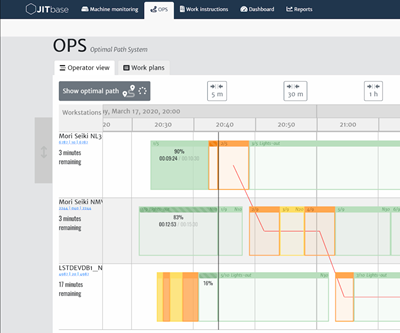

Read MoreMapping the Optimal Path for Machinists

Using data from machine monitoring systems and CNC programs, OPS calculates the most efficient path for operators to take across the shop floor, improving uptime and increasing machines per operator.

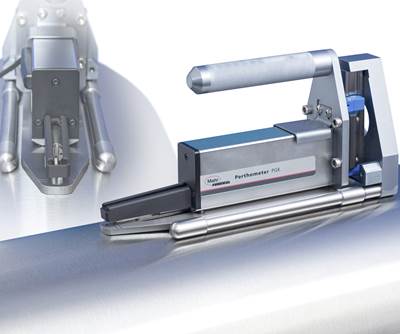

Read MoreHow To Measure Surface Roughness on Large Parts

Performing surface finish measurements on large or complex parts can be made much easier with properly designed fixturing.

Read MoreCNC Machining as a Business Strategy for 3D Printing

As the additive manufacturing company 3rd Dimension Industrial 3D Printing prepares for production, it has one critical advantage over the competition: a standalone CNC machine shop.

Read MoreAdjusting Supply Chains in U.S. Manufacturing

As the novel coronavirus presents challenges for manufacturers and new opportunities for suppliers, manufacturers should not miss the chance to strengthen their supply chains.

Watch