-

SPONSORED

-

SPONSORED

MMS Blog

November 2019 Product Spotlight: 5-Axis Machining

This month’s Modern Equipment Review Spotlight focuses on five-axis machining technologies.

Read MoreThe Tie Between Technology and People

Top Shops data analysis shows that investment in employees more directly correlates to profit margin than investment in equipment. Still, careful consideration of new technology matters.

Read MoreSix Ways to Make 5-Axis Machining More Productive

Five-axis machining is growing in popularity because of the dramatic efficiencies it can bring in an increasingly broad range of applications — from aerospace to medical to production parts as well as dies and molds. Good CAM software is critical to unlocking that potential.

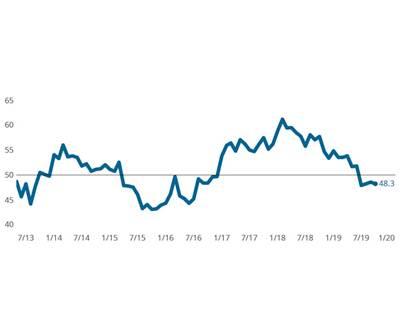

Read MoreMild Metalworking Index Contraction Extended

The Index posts mild contraction despite growing new orders.

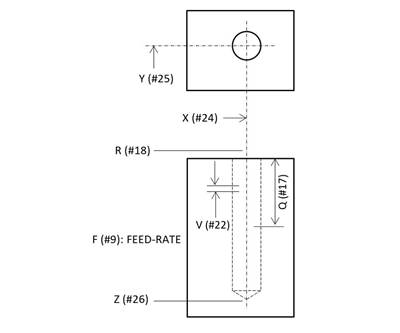

Read MoreHow to Improve Peck Drilling Canned Cycles

Most CNCs don’t have a canned cycle for machining deep holes into malleable materials. Here’s what you do.

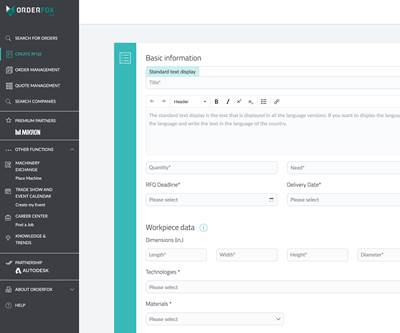

Read MoreMetalworking News of Note: November 2019

Orderfox.com adds an RFQ service for its users, Sandvik Coromant begins construction on new tech center in North Carolina, and other news from the metalworking industry.

Read MoreWhat Can 3D Printing Really Do?

And what will it mean for the future of manufacturing? “The Cool Parts Show,” a new video series from Additive Manufacturing, answers these questions with real examples. Watch the first season now.

Read MoreWhat Can 5-Axis Machining Do for Your Shop?

If you haven’t looked at 5-axis machining lately, a lot has changed. Advancements in 5-axis machines, controls and software have made this technology so affordable and easy to use that it can benefit almost any shop.

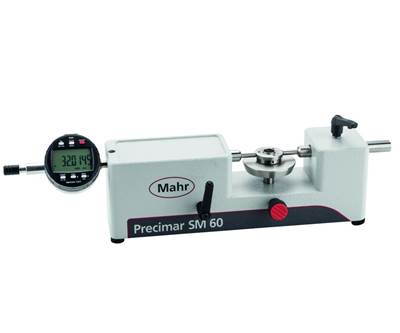

Read MoreGetting More with Digital Indicators

Today’s digital indicators are not only replacing dial indicators in some instances, but they are also approaching the performance of bench amplifiers at a fraction of the cost.

Read MoreFabricator's Toolroom Becomes Captive CNC Machine Shop

Toolroom problem-solving yields high-production profit when a sheet metal fabricating business accepts a difficult machining contract.

Read MoreVideo: How to Succeed at Lights-Out Machining — Findings from Top Shops Data

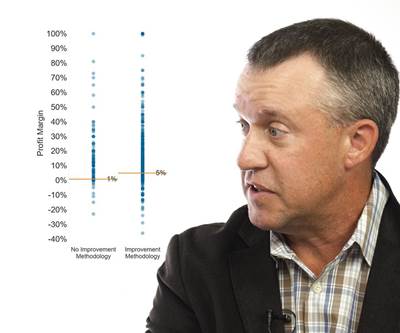

Differences in machine shops’ profit margins suggest the value of improvement methodology, unattended machining and machine tool monitoring, as well as the effective combination of all three of these.

Watch6 Ways to Reduce Outstanding Receivables

Are you effectively following up on your receivables?

Read More