-

SPONSORED

-

SPONSORED

MMS Blog

Advancing Cutting Tool Production with Electrical Discharge Grinding

A wider power range and new erosion control features enable users of ANCA’s EDG machines to more quickly produce cutting tools that last longer.

Read MoreMetalworking Index Holds Steady After Scorching First Quarter

The Gardner Business Index: Metalworking held at a reading of 62.2 through April, indicating a constant level of expansion.

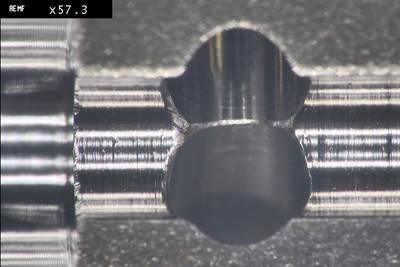

Read MoreCross-hole Deburring Tool Eliminates Secondary Process

The Orbitool from J.W. Done helped Paramount Machine eliminate a secondary deburring process, saving 75 process hours across a 2000-part run and enabling the shop to meet its profit and delivery time goals.

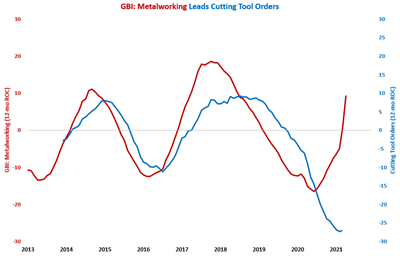

Read MoreMarch Cutting Tool Orders Highest in 13 Months

March cutting tool orders were $177.6 million, close to pre-lockdown level. GBI: Metalworking Index indicates cutting tool orders will increase through 2021.

Read MoreChallenges Reveal Value and Vulnerability of Small Machine Shops

Small business ownership is conducive to the kind of oversight and commitment that serves machining well, but small business also relies on the support and commitment of enterprises around them.

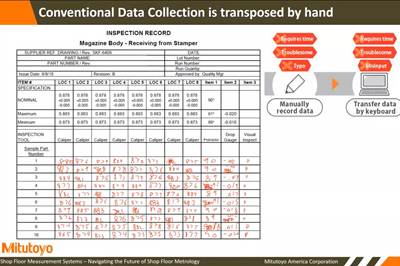

Read MoreImplementing Digital Shop Floor Metrology

In a recent webinar with MMS, Michael Creney, Mitutoyo America’s vice president of product management, outlined the benefits of digital shop floor metrology and delivered tips for adopting it.

Read MoreCeramic End Mill Achieves Long Life and High MRR at Standard Machining Center Speeds

Material advances have produced a ceramic end mill that performs well at lower cutting speeds and competes with carbide in a broad range of applications. Your shop might begin using ceramic tools.

Read MoreCalling Custom Macros Through Modal Commands

While G65 does not enable users to simply and easily carry out Custom Macros in multiple locations, G66 and G66.1 provide modal solutions for doing so.

Read MorePower Skiving Enables Smaller, Precise Robotics Machining

Power skiving tools like Sandvik Coromant’s CoroMill 178 can increase productivity, precision and flexibility when machining gears for applications such as industrial robotics.

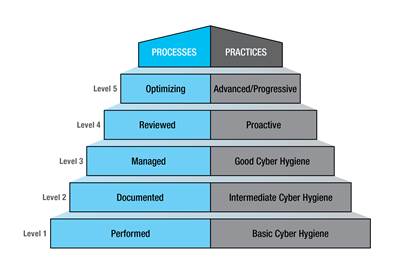

Read MoreCybersecurity Process Maturity Demands a Plan

Plans may fail, but planning has intrinsic value for building sustainable, adaptable data defenses.

Read MoreRethinking MRO Challenges with Desktop Metal's Studio System

The second-generation Studio System simplifies the design process and eliminates common safety hazards of metal AM, increasing accessibility for manufacturers.

Read MoreThe Case for Automatic Door Operation

Automatic door systems for stand-alone machine tools require periodic inspection and maintenance, but excel in environments with automation capability or frequent door use.

Read More