-

SPONSORED

-

SPONSORED

MMS Blog

Nidec Acquiring Mitsubishi Heavy Industries Machine Tool

Motor manufacturer looking for ways to more efficiently manufacture so it is buying a machine tool company

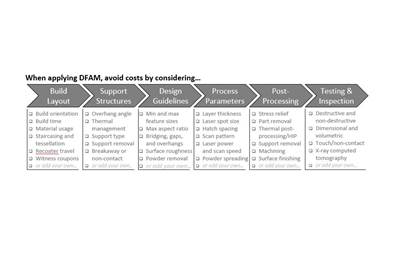

Read MoreAvoiding Costs while Adding Value with DFAM

Design for Additive Manufacturing (DFAM) is as much about finding value as it is about avoiding costs with AM.

Read MoreMachine Tool Orders Boom in December 2020

Machine tool orders reached their highest level since September 2018 (the last in-person IMTS) and their highest level outside of an IMTS month in three years.

Read MoreMoving Monitoring Closer to the Cut

A sensory toolholder can provide more accurate vibration data on the metalcutting process, helping to extend tool life and improve surface finish.

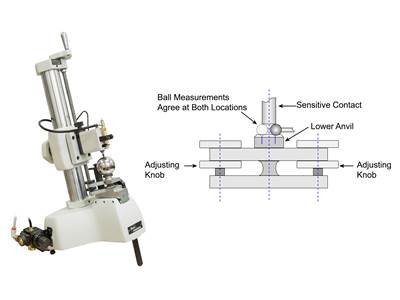

Read MoreConfirming Dimensional Accuracy of a Precision Ball

A single diameter isn’t the only measurement parameter that can be used to ensure accuracy.

Read MoreTPEI Takes on Larger Parts, Increases Efficiency with Romi Lathes

After adopting the Romi C 830 and C 510, TPEI can turn larger workpieces and take larger depths of cut compared to its previous lathes.

Read MoreMeet the 3D Printed Parts That Are on Their Way to Mars

Five components of a critical instrument were made via electron beam melting, a technique able to deliver the hollow box beams and thin walls. But 3D printing was just the first step.

Read MoreMazak Takes Entry-Level Machine Tools to New Heights

A new machine series aims to address the immediate and longer term requirements of job shops by lowering cost barriers to acquiring manufacturing technology without foregoing capability or compromising performance.

Read MoreNew Horizons with a New Horizontal Machining Center

A sudden surge in orders for a part used in COVID diagnostic equipment forced CBM Industries to quickly adapt to its first horizontal machining center, including the challenges of fixturing and lights-out machining.

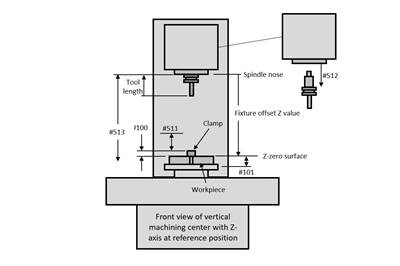

Read MoreT Codes Simplify Tool Length Confirmation Process

CNC users can program custom macros and T codes to ensure cutting tools are the proper length for tool length compensation in machining centers.

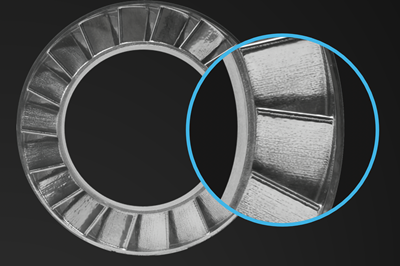

Read MoreHere Is Why Knust Godwin Decided to 3D Print Mission Critical Parts

Knust Godwin introduced metal 3D printing into its precision-machining environment nearly eight years ago. Now the company is using the capability to break through into new applications and give 3D printed mission-critical parts a renewed business case.

Read MoreERP Makes Social Distancing Possible at Make-to-Order Shops

As we all learn to cope with the realities of the COVID-19 pandemic, the case for cloud-based ERP has never been clearer.

Watch