George Schuetz Director of Precision Gages

Why A Negative MPE May Be Very Positive

Specifications for metrology equipment are usually published in nice glossy brochures that have lots of great pictures highlighting all the features of the product. But specifications can be confusing and are often a hot topic of debate.

Read MoreGetting The Most From Your Portable Surface Gage

Portable surface gages have come a long way in the past 25 years. Instruments that once encompassed three separate pieces, took a hand cart to move and cost tens of thousands of dollars can now be carried in the palm of your hand.

Read MoreMasters For Comparative Gages

Most masters used for setting comparative gages look like everyday gage blocks, master rings or discs. However, ASME standards for these masters are very specific in defining their characteristics, including material, physical sizes and geometric conditions.

Read MoreThings You Should Know About Digital Height Gages

With its long range of motion, the digital height gage can be thought of as a giant caliper, but one with the accuracy of a sophisticated benchtop gaging system. These versatile digital height gages are capable of performing a range of measuring tasks quickly and reliably.

Read MoreThe Right Angle On Perpendicularity

In nature, a right angle happens only by chance. But the importance of this concept—which results from the perpendicular intersection of lines or surfaces—applies to architecture, civil engineering, agriculture and manufacturing.

Read MoreTracking Down Tracking Errors

In the world of dimensional measurement, electronic gages make up a class of instruments that are capable of detecting extremely small dimensional variations on a surface element. The gage's electronic transducer can operate in a number of different ways, typically LVDT (Linear Variable Differential Transducer) or through a digital scale-based technology.

Read MoreLocking It In With A Good Taper Fit

A machined taper fit between mating parts is a fast and secure way to put two parts together. Fast mating and good alignment make taper fits critical in two very different fields.

Read MoreGaging Tighter Tolerances Is A Different Animal

If you are planning on manufacturing to tolerances of 0. 0001 inch or less and have not done so before, your introduction to high order gaging might be an eye opener.

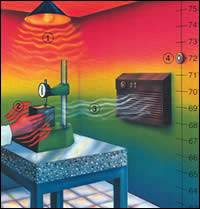

Read MoreGage Accuracy Runs Hot And Cold

“It takes a while to warm up in the morning, but after that, it runs great. ” I swear that machinists apply this statement to their gages as if the instruments were like car engines with 50-weight motor oil and cold-intake manifolds.

Read MoreWhen Gaging Becomes Measuring That Becomes Gaging

In a previous column, we discussed the terms “gaging” and “measuring,” which are often used interchangeably. There are times when gaging is appropriate and other times when measuring is the best way to go.

Read MoreGive Your Mechanical Snap Gage A 50,000 Mile Checkup

Your snap gages have been out on the shop floor for years and have served you well. Normally they are zeroed with a zero master, measurements are made and all is well.

Read MoreTime To Re-Evaluate Your Gaging?

Let’s say you’ve been making the same part for decades, running hundreds or thousands of parts every day, from the same machines, using the same process and the same gaging purchased when the process was started. If this is the case, then you’re not alone.

Read More