John Miller President

Tips for Investing Intelligently When Upgrading a Shop on a Budget

Working on a tight budget is not easy, but these tips can help you make the most of your free capital.

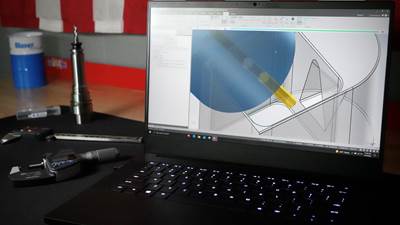

Read MoreAdjusting CAM Tolerance and Machine Modes to Fix Faceting Issues

Fixing an issue often requires fine tuning of both CAM tolerances and the machine mode for full optimization and process reliability.

Read MoreHow to Optimize Operator Efficiency on Any Shop Floor

Striking the perfect balance of person to machine is unique to each shop and can depend on a number of factors, including the type of work a shop undertakes, the available equipment, staffing levels, scheduling and more.

Read MoreConsiderations for Properly Implementing Advanced Tool Materials

Many shops incorrectly assume advanced tools are plug and play. The tools may fit into existing tool holders, or even into the same shell mill pockets or turning pocket as carbide inserts, but that’s where the similarities end.

Read MoreStrategies for Expanding a Shop the Right Way

It’s very easy to get paralyzed by all the directions you can go when upgrading a shop, but breaking this decision into its simplest forms can help curb future buyer’s remorse.

Read MoreSolving Process Issues With a Detail-Oriented Approach

It is essential for a machinist and a shop to have the discipline to pause a process and reassess when encountering issues, even when schedules are tight.

Read MoreProcess Modernization is Scary but Necessary

When done correctly, process modernization can help secure a shop’s future in the industry and open new opportunities.

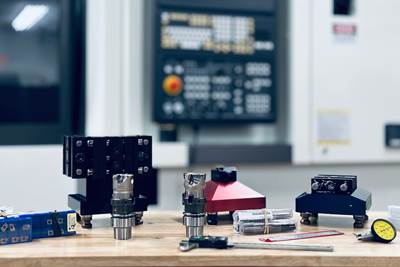

Read MoreSecuring Processes for Automation

Securing a process for reliable automation takes much consideration, but many modern machines have features that can help.

Read MoreHow Lowering Torque Improves Tapping Tool Life

Escaping the tap breakage trap requires a long look at torque and the many factors that influence it.

Read MoreSolving Holemaking Issues: Boring or Reaming?

Single-point boring and reaming are both excellent ways to meet high tolerances and finish requirements for hole making, but each has distinct specialties.

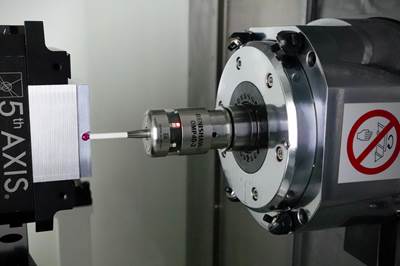

Read MoreWhat Should Machinists Know About In-Machine Probing?

In-machine probing doesn’t reach the power of CMMs but can still be useful for pre- and mid-process control, as well as for “rough screening” of parts.

Read MoreHow to Tackle Tough Angled Pocket Milling With Two Tools

Milling a deep pocket with a tight corner radius comes with unique challenges, but using both a flat bottom drill and a necked-down finishing tool can help.

Read More