Julia Hider Senior Editor

Growing a Job Shop into a Full-Service Manufacturer

By maximizing employee satisfaction, adding fabrication and other services, and always keeping open machine capacity, Square Deal has grown from a seven-person job shop to a full-service manufacturer that employs hundreds.

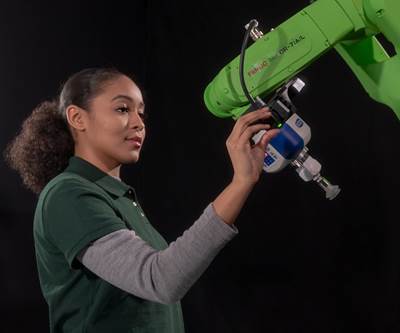

Read MoreSimplifying Job Shop Automation with Hand-Guided Robots

Easy to implement and flexible enough to handle a range of applications, hand-guided robots can help job shops automate high-mix, low-volume production.

Read MoreDeciding to Specialize as an Aerospace Supplier

Formerly a job shop serving a diverse local customer base, IPG responded to industry changes by transitioning into becoming an aerospace supplier. Here are the steps the shop is taking to make that change, including adding equipment and implementing plans for quality and marketing.

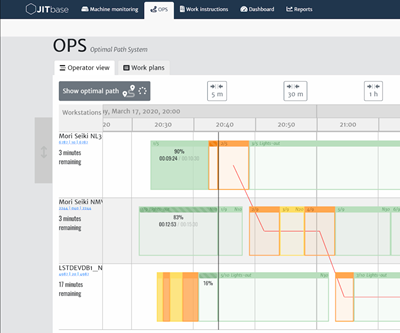

Read MoreMapping the Optimal Path for Machinists

Using data from machine monitoring systems and CNC programs, OPS calculates the most efficient path for operators to take across the shop floor, improving uptime and increasing machines per operator.

Read MoreMulti-Pallet Machines Help Shop Produce Ventilator Components

NRL & Associates’ business plan relies on using multi-pallet machines for unattended machining, so when two of its customers increased production of ventilators, the shop quickly brought in a new multi-pallet machine and automation system to meet the demand.

Read MoreBecoming a Second Source for Ventilator Parts

Demand for ventilator parts stretched this shop’s supply chain. Here is what it took to rapidly insource production.

Read MoreCAM System Smooths Shop’s Transition to Ventilator Part Production

Pindel Global Precision’s CEO used his Navy SEAL experience to help his shop navigate the switch from one CAM system to another while manufacturing new ventilator parts in the middle of a pandemic.

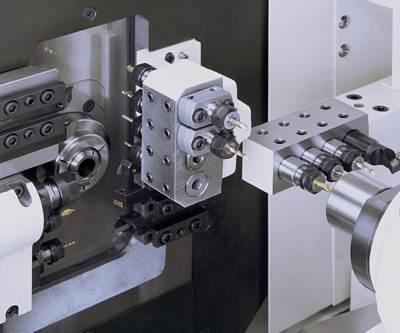

Read MoreNew Business Plan Enables Shop to Increase Ventilator Part Production

KrisDee and Associates was able to increase production of a ventilator manifold from 90 parts per week to 780 parts per week thanks to changes the company started making months earlier.

Read MoreManufacturing Association Aids Shop’s Pivot to Ventilator Parts

After reaching out to the Austin Regional Manufacturers Association, a shop that typically serves oil and gas and heavy industry was able to quickly fill an order for ventilator parts.

Read MoreFacilitating Remote Work, Social Distancing with ERP Systems

As long as shops take steps to prepare, they can use their ERP systems to enable many employees to work from home and increase social distance for those who need to be in the shop during the coronavirus pandemic.

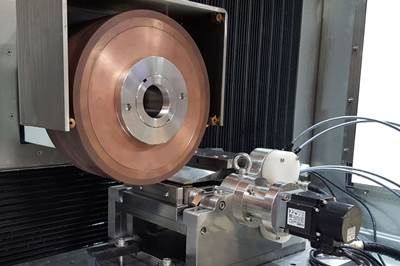

Read MoreNew Applications for Electrochemical Grinding

With advances in control, sensor and automation technology, electrochemical grinding is more accurate and productive than ever, opening up new applications for the traditionally niche process.

Read MoreInspection System Helps Company Meet Short Lead Times

Even after buying new fast machine tools, inspection remained a bottleneck for BCI. A digital video inspection system from Starrett is increasing this company’s inspection throughput and helping it get parts to its customer on time.

Read More