Julia Hider Senior Editor

Grinding Technology Prepares Manufacturers for Business Challenges

Studer’s automation solutions, S100 flexible grinding machine and intelligent coolant system can help users with unattended machining, machining a range of workpieces and saving energy.

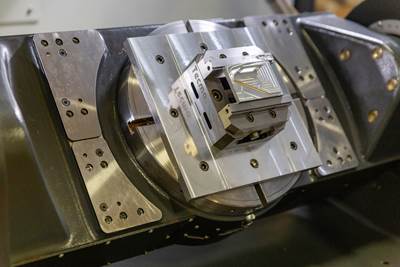

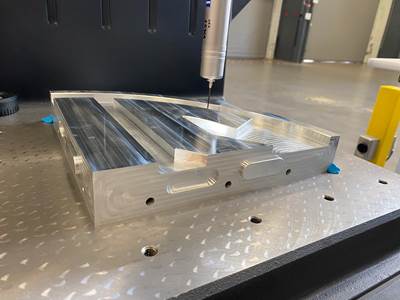

Read MoreThe Benefits of Vertically Integrating Metal 3D Printing and Machining

Having 3D printing and machining within one organization enables Addman’s engineers to collaborate and consolidate so it can quickly make successful metal 3D printed parts.

Read MoreDiving Deeper Into Machine Monitoring Data

Data visualization is the first step in using machine monitoring data, but taking it to the next level requires looking for trends within the data.

Read MoreBenchmarking: An Invaluable Business Tool

91ÊÓƵÍøÕ¾ÎÛ’s Top Shops program shows shops their strengths and opportunities for improvement, and provides recognition for high-performing businesses.

Read MoreManufacturing Madness: Colleges Vie for Machining Title (Includes Video)

The first annual SEC Machining Competition highlighted students studying for careers in machining, as well as the need to rebuild a domestic manufacturing workforce.

WatchSwiss-Type, Live Tooling Lathes Help Turn Company Around

New leadership’s investment in Swiss-type and live tooling lathes has enabled Rathburn Tool & Manufacturing to expand into new markets, reversing the company’s sluggish growth.

Read MoreBetter Together: Combining Cobots and Palletization

Using a collaborative robot to tend a machine with a pallet changer can help shops maximize unattended machining time.

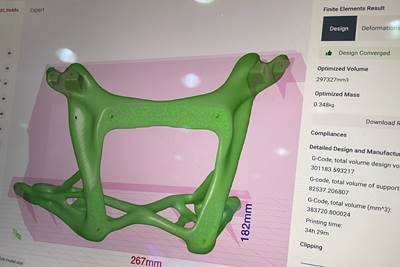

WatchFive Digital Manufacturing Trends Reflected in 3D Printing and Machining

As the digitization of machining accelerates, it’s seeing more crossover with its innately digital relative, additive manufacturing. On this episode of AM Radio, Julia Hider and Matt Danford discuss common themes in machining and 3D printing.

ListenPreparing a Shop for Automation

Ensuring a stable, predictable production process can prevent automation from multiplying existing problems.

Read MoreUsing (And Scaling) FDM 3D Printing for Production

Maxwell June’s razor press, which is designed to combine the ease of use of a disposable razor with the environmental and cost benefits of a wet shaving system, is made via FDM 3D printing. How did the company make this choice, and how does it plan to scale up?

WatchNew Machining Technology Works With Old to Restore WWII Submarine

A set of donated boring bars that can be used in a 1954 boring head will enable volunteer machinists to recreate a pair of binoculars for the USS Pampanito.

Read MoreHTML-Based HMI Puts Users in Charge of Machine Customization

By building a human-machine interface using more accessible HTML instead of a custom API, users will be able to more easily customize their machine controls, making them easier to use, more secure and ready for Industry 4.0.

Read More