Mitsui Seiki (USA) Inc.

563 Commerce Street

Franklin Lakes, NJ 07417 US

201-337-1300

info@mitsuiseiki.com

CONNECT

About Mitsui Seiki (USA) Inc.

We combine our engineering, sales support, service, and spare parts responsibilities with a strong distributor network covering the U.S.A, Canada, and Mexico to provide the best possible communication, and industry networking.

IS THIS YOUR COMPANY?

As Seen On 91ÊÓƵÍøÕ¾ÎÛ

Mitsui Seiki (USA) Inc. Supplies the Following Products

- for Metal Parts

- Graphite Milling

- Horizontal, Five-Axis

- Horizontal, Up to Four-Axis

- Jig

- Jig Boring

- Lasers, Nd: YAG, Pulsed

- Machining Flex Lines

- Thread

- Universal

- Vertical, Five-Axis

- Vertical, Up to Four-Axis

Trade Names Offered by Mitsui Seiki (USA) Inc.

- Vertex

- Mitsui Seiki

Editorial, News, and Products

-

Mitsui Seiki Appoints Directors of Sales East, West

Mitsui Seiki USA Inc. appoints Joseph Farkas as its director of sales West and Terry Ritterbush as its director of sales East.

-

Mitsui Seiki Machining Centers Enable Repeatable Production

IMTS 2024: Mitsui Seiki showcases three versatile, accurate machining centers.

-

Should Blisk Machining be in Your Growth Plan?

Blisk machining offers a great business opportunity but requires technical expertise in machining difficult materials with multi-axis machines. The right partner can help you get started.

-

Multitasking Machines Cut Days From Shop’s Setups

Adopting WFL Millturn machines enabled BWXT to condense operations and setups while also providing a simple way to simulate and secure processes.

-

JTEKT Technology Days Showcases Synergies

The event took place following the company’s completion of its new showroom and decision to merge several of its brands under the JTEKT name.

-

Mitsui Seiki USA Appoints New President

Daniel Cleary plans to focus his attention on the company’s investment in people, technology and infrastructure.

-

Mitsui Seiki's Compact VMC Offers High-Precision Milling

The VL30 series is designed to machines high-precision mold inserts for medical, packaging, industrial and aerospace applications.

-

Mitsui Seiki USA Launches New Line of Jig Borers

The J12/J/16 jig borer series feature a durable structure that provides table lateral movement accuracy of 2.5 µm or better.

-

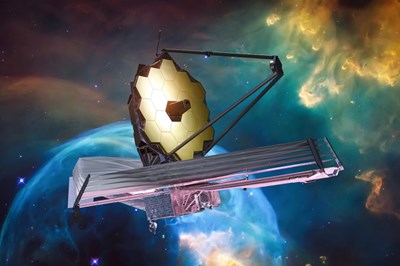

Volumetric Accuracy Is Key to Machining James Webb Telescope

To meet the extreme tolerance of the telescope’s beryllium mirrors, the manufacturer had to rely on stable horizontal machining centers with a high degree of consistency volumetric accuracy.

-

NASA Brings Technology to New Heights

Meet NASA mission system engineer Mike Menzel and learn more about the James Webb Space Telescope at Mitsui Seiki USA’s booth (338700) in the South Hall from 11:00 a.m. to 11:45 a.m. on Thursday, September 15.

-

Out of This World: Space Exploration Innovations at IMTS

The more time passes, the more it becomes clear that space exploration and manufacturing have a close-knit future together. (Click through for a slideshow of the coolest space gear we found on the show floor!)

-

Five-Axis Machining Center Accommodates Small Workpieces

Mitsui Seiki’s compact PJ 303X machining center, to be highlighted at IMTS 2022, provides high precision, speed and versatility for critical parts like lens molds, medical products and EDM electrodes.

-

Digital Twins Give CNC Machining a Head Start

Model-based manufacturing and the digital thread enable Sikorsky to reduce lead times by machining helicopter components before designs are finalized.

-

Mitsui Seiki Installs First Blue Arc Machine

Mitsui Seiki has installed what it says is the first Blue Arc-using machine tool. Blue Arc uses a multiple-point discharge event for material removal, whereas EDM uses a single-point discharge.

-

Mitsui Seiki VGi20A Grinding Machine Speeds Nut Processing

Mitsui Seiki’s VGi20A Ball Screw Nut Grinding Multitasking Machine combines grinding and machining in a single chucking to shorten nut processing time.

-

Mitsui Seiki J Series VMC's Thermal Sensors Maximize Accuracy

Mitsui Seiki J Series VMCs are designed to maximize accuracy in precision boring, milling, drilling and tapping.

-

Mitsui Seiki's J350G Jig Grinder Enables Various Operations Without Wheel Change

The Mitsui Seiki J350G jig grinder is designed to provide a combination of application flexibility, accuracy and user-friendly operation.

-

November 2019 Product Spotlight: 5-Axis Machining

This month’s Modern Equipment Review Spotlight focuses on five-axis machining technologies.

-

Mitsui Seiki's HU100-TS Five-Axis HMC Presents Alternative to Trunnion Machines

Mitsui Seiki’s HU100-TS tilting-spindle five-axis horizontal machining center is built to machine large and hard workpieces that may be better suited for tilt-spindle processing than trunnion-table operations.

-

Mitsui Seiki Celebrates 90 Years

Mitsui Seiki celebrated 90 years with a formal dinner, speakers and entertainment in Tokyo, Japan.

-

A Collection of Company Newsletters by Mitsui Seiki’s Scott Walker

Learn, teach and repeat became the formula that generated a long series of company newsletters. The best of the teachings from these newsletters have been gathered into a readable, enlightening book.

-

A Literal "New Spin" on Hybrid Milling/Grinding Machines

Mitsui Seiki’s Vertex hybrid machine borrows a jig grinder’s motion to complement high precision five-axis milling.

-

“Rantings of a Machine Tool Salesman” to Be Released During IMTS 2018

The book is described as a sometimes funny, sometimes serious, sometimes sentimental collection of the author’s favorite selections taken from bi-weekly newsletters spanning 20 years.

-

Five-Axis Series Targets Tooling, Optics

IMTS 2018: Mitsui Seiki USA Inc.’s Vertex Hybrid G series of five-axis VMCs (models 55-5X, 75-5X and 100-5X) offer lights-out milling and grinding of die and mold, optical, and tooling components.

-

VMC Precisely Machines Large Blisks

IMTS 2018: Mitsui Seiki’s Vertex 100 five-axis VMC is designed for precision milling of large parts, such as blisks for aircraft engines.

-

Five-Axis VMC Handles Large Aircraft Components

Mitsui Seiki’s Vertex 100 5-axis vertical machining center is a high-speed, high-precision milling machine for larger parts such as blisks for aircraft engines.

-

Mitsui Seiki, TechSolve to Demonstrate Blue Arc Method

The companies will showcase the Blue Arc electro-erosion metal removal method and demonstrate how it can quickly rough cut tough superalloys.

-

Machining Titanium Aluminide at AeroEdge

Japanese manufacturer AeroEdge has had success in machining turbine blades from challenging TiAl through a combination of customized VMCs and cutting tools designed in house.

-

Precision and Custom Solutions Showcased at Mitsui Seiki

A tour of the company’s factory in Japan highlighted the accuracy of its machine tools as well as their adaptability for specific applications.

-

Mitsui Seiki USA Appoints Chairman, CEO, COO

Together, they will manage inventory mix, business strategy development and implementation, and financial oversight.

-

Integrating Additive Manufacturing without Inhibiting Machining

CNC machining is the superior process for dimensional precision. Can AM be added to the machine tool without compromising this strength?

-

HMC Features Quill Spindle for Boring Oilfield Parts

The quill spindle model of Mitsui Seiki’s HU100 heavy-duty HMCs is designed for precision boring of large parts in energy-related as well as other industries.

-

Five-Axis Machine Line Delivers High-Accuracy Features for Aerospace Work

Mitsui Seiki’s Vertex 55X II line of machines expands on the Vertex 550-5X line.

-

A Compact but Rigid VMC for Machining Titanium Blades

In recent years, machine tool builders have developed models specifically designed for the efficient machining of titanium and other hard metals.

-

Blade Center Machines Titanium, Stainless Steel

Mitsui Seiki offers the Vertex 550-5XB blade center for producing turbine blades from forgings, castings, barstock or solid billets of titanium and stainless steel.

-

How One Job Shop Tackled Tungsten

When this aerospace job shop settled on machining tungsten alloys and other heavy metals as its specialty, it had to have a machine tool, cutting tools, workholding and process know-how to succeed.

-

What JIMTOF Had to Show Us

We present here some of the interesting and visually appealing snapshots from JIMTOF 2012.

-

Five-Axis Machining Center Designed for Power-Generation Applications

Mitsui Seiki’s HU63-T five-axis CNC machining center is designed for power-generation applications, including critical rotating components such as blisks, impellers and turbine disks, as well as gas-turbine power-generation systems.

-

Design the Parts Around the Process

To guarantee that components for a new helicopter could be readily produced, the company looked at the capabilities of available machine tools in the market first, and then finalized the design of the components accordingly. It created a Precision Components Technology Center to embody this concept as a process for R&D prototype work. What has emerged is a flexible production model that can be duplicated at its other facilities.

-

Disaster in Japan: A Spirit of Generosity Will Prevail

Despite last week’s horrendous disaster, Japan will carry on.

-

Cutting Spiral Bevel Gears On A Five-Axis Machining Center

To produce high-precision ring gears in low- to mid-volumes, an emerging option is the use of five-axis machining centers. Mitsui Seiki CNC vertical and horizontal machining centers are being used in this application.

-

What Is The Right Machine Tool For Titanium?

Rather than start with the machine, says Boeing, start with the tooling. For titanium workpieces and other high-value parts, a simple spreadsheet of tools and operations might be the most valuable resource for machining center selection.

-

How One Shop Machines Advanced Ceramics

Years of trial and error combined with the appropriate machining technology allow this company to produce custom parts made of alumina, zirconia, boron nitride and other advanced ceramic materials. One example of key machining technology is a five-axis machining center used exclusively to produce the complex, tightly toleranced geometry that fire-hardened workpieces require.

-

Keeping Accuracy Within Reach

Part quality is at risk if a machining center cannot hold tolerances at the farthest reaches of its work envelope. This makes volumetric accuracy a key indicator of a machine's performance. One machine tool builder discusses the implications.