-

SPONSORED

-

SPONSORED

-

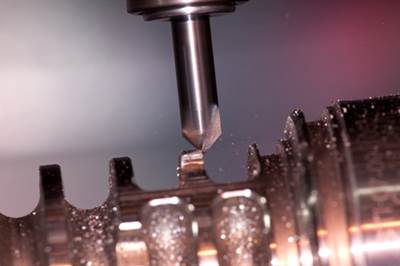

CNC & Machine Controls

How to Improve Machining Center Accuracy

Accuracy is not just inherent to the machine—it also depends on how the machine is used. Try these techniques to let a new or existing CNC machining center achieve its potential precision.

Read MoreVideo: Automatic Part Verification Through Reference Comparison

The machining center in this automated production process inspects its own work and updates its own positioning. Probing a known, traceable reference makes this possible.

WatchAbsolute Linear Encoder

Incorporating absolute technology to a multi-substrate scale tape linear encoder design, Heidenhain introduces the LIC 4000. Besides its capability of absolute position measurement, this encoder is characterized by its high resolution of 1 nanometer and its serial EnDat 2.

Read MoreSoftware Delivers Lean Production Control

GE Fanuc Intelligent Platforms, a unit of GE Enterprise Solutions, offers Proficy Tracker 8. 0, a lean production control that manages inventory, schedules resources in real-time and controls the routing of material through a discrete manufacturing process.

Read MoreWindows-Based HMI Uses Flashcard Technology

The Bosch Rexroth IndraControl VEP series of PC-based human/machine interfaces (HMIs) provides PC power and functionality with an embedded Windows CE operating system. The system uses flashcard technology and multiple operator platforms, allowing equipment designers to choose the best configuration for each machine application and environment.

Read MoreBed Mill Operates Manually Or With CNC

The Trak DPM SX5 bed mill with the ProtoTrak SMX control may be operated manually or as a two- or three-axis CNC. The solid ram moves up and down for Z-axis operation, providing mass behind heavy cuts.

Read MorePlug-And-Play CNC Monitoring

These CNC monitoring appliances are preloaded for detailed reporting, e-mail notifications, cell phone notifications and real-time CNC status display for plug-and-play installation.

Read MoreCNC Increases Productivity For Aerospace Applications

The Sinumerik 840D is said to increase performance and user productivity on the manufacturing floor, especially for high-speed and five-axis aerospace machining. The solution line is a universal and flexible CNC system featuring Sinamics S120 drives that can be used for as many as 31 axes. It is a distributed, scalable, open and inter-connecting system that offers a range of specialized functions for milling, drilling, turning, grinding and handling technologies.

Read MoreToo Small To Touch

Hummingbird takes on machining work that is too small for most shops to handle. In fact, Hummingbird tries not to handle it either. To accurately machine the tiniest parts, this shop relies on processes that are as hands-off as possible.

Read MoreLittle Things Mean A Lot

The design of a machining center with the precision to mill tiny features illustrates what is (and is not) required for micromachining.

Read More