-

SPONSORED

-

-

CNC & Machine Controls

Putting Flexible Controls in Users’ Hands

At IMTS 2022, Heidenhain is launching programs that make getting its controls as simple as using them.

Read More5 G-Code Tips for Increasing CNC Efficiency

Optimizing G code is a low-cost way to improve CNC efficiency without sacrificing usability and safety.

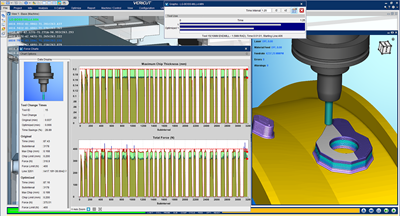

Read MoreCGTech Demonstrates Vericut 9.3

The latest version of CNC simulation software incorporates improvements and new features focusing on using data for more informed manufacturing.

Read MoreUnderstanding G27, G28, G29 and G30

Take a closer look at these reference position commands.

Read MoreUnderstanding CNC Machine Accuracy and Repeatability

Properly evaluating machine tool capability requires understanding how the both user and the builder can influence precision.

Read MoreCNC Simulation Software Uses Data for Smarter Manufacturing

The latest version of CNC simulation software incorporates enhancements and new features focusing on using data for smarter, more informed manufacturing.

Read MoreWhen to Use Custom Macros With a CAM System

Custom macros can offer benefits even when using a CAM system to prepare programs – but must be implemented with the right considerations.

Read More6 Steps to Take Before Creating a CNC Program

Any time saved by skipping preparation for programming can be easily lost when the program makes it to the machine. Follow these steps to ensure success.

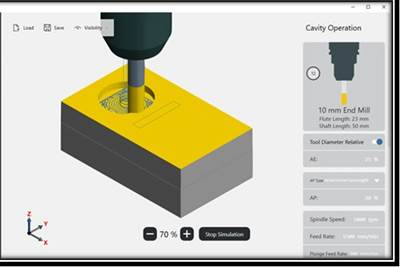

Read MoreShopfloor Software Simplifies On-Control Programming

ModuleWorks offers its Next Generation Shopfloor Programming, designed to enable machine tool operators to build, simulate and run NC programs without G-code expertise.

Read MoreKey CNC Concept No. 1—The Fundamentals Of Computer Numerical Control

Though the thrust of this presentation is to teach you CNC usage, it helps to understand why these sophisticated machines are so important. Here are but a few of the more important benefits offered by CNC equipment.

Read More