Deburring

Grit-Blast System for Precision Surface Preparation

Guyson’s model RB-72 extended-height robotic blast machine features a 72" × 72" work envelope and pressure-blast media delivery for precision-surface preparation applications in the aerospace industry, including composite structures.

Read MoreTwo-Head Deburring System Completely Deburrs Parts

Abtex’s expanded Tri-Ten deburring line includes a two-head, U-series, high-productivity system.

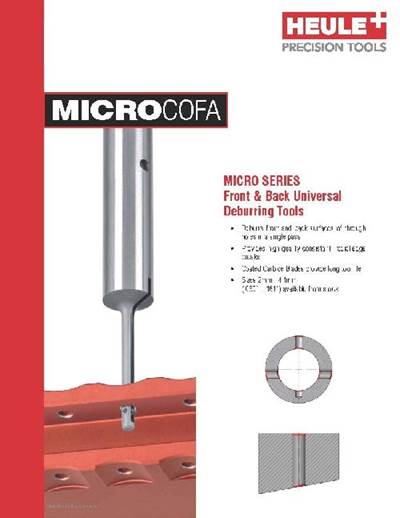

Read MoreMicro-Carbide Tools for Deburring

Heule Precision Tools offers a catalog on its Micro Cofa series of front and back universal deburring tools.

Read MoreLive Tooling for Limited Space

The Stubby series of deburring tooling from E-Z Burr is designed for use in modern Swiss-type machines.

Read MoreHone Offers Finishing Flexibility

Brush Research Manufacturing offers two examples that showcase how its Flex-Hone hole-finishing tool can help manufacturers meet exacting surface finish requirements both in the shop and in the field.

Read MoreBand File Deburrs Hard-to-Reach Places

The BFE 9-90 electronic band file is designed for metal removal and deburring in hard-to-reach places.

Read MoreAutomatic, Low-Cost Deburring of Small Parts

Almco’s Model VM-1 VibeMaster is a portable, round-bowl machine with a ½-cubic-foot capacity for deburring and finishing small metal parts in job shops and metalworking departments.

Read MoreHow Electro-Chemical Machining Works

Machine tool builder EMAG has produced a very nice video that explains and illustrates how the electro-chemical machining (ECM) process is able to perform simple deburring operations as well as produce precision surfaces and shapes.

Read MoreControlling Burr Formation within Small Intersecting Holes

A reader struggles with burrs between intersecting holes 1 mm and less in diameter. MMS Online’s micromachining expert offers advice.

Read MoreBrush Hone Boosts Safety, Productivity, Finish Quality

This manufacturer recently employed the Flex-Hone ball-style honing brush from Brush Research Manufacturing to automate the finishing of die bores. In addition to providing quality and productivity improvements, the tool helped eliminate the potential for operator discomfort and injury.

Read More