-

SPONSORED

-

-

Shop Management Software

Automation and Process Simplification Define Eastec 2023

Manufacturing technology at this year’s Eastec met the market with tools to streamline operations and assist machinists in achieving greater productivity.

WatchSimulation and Tooling Secure High-Value Work

Simulation software and careful attention to tooling parameters have enabled Major Tool to take on ambitious projects with its complex machinery.

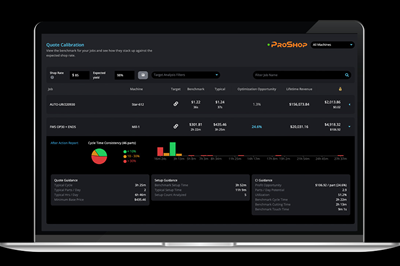

Read MoreDatanomix's Analytics Solution Visualizes Shop Performance

Eastec 2023: The Automated Job Costing automatically matches part numbers in Datanomix to those from the ProShop ERP system and extracts specific target takt times.

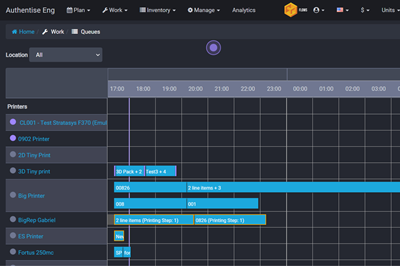

Read MoreAuthentise MES Software Provides Real-Time Quoting

Flows and FlowsAM include features such as data-driven status updates, material genealogy, supplier management and more.

Read MoreProShop's Cloud-Based ERP Solution Increases Data Security

Eastec 2023: ProShop SAFE is designed to ensure data security compliance to the NIST 800-171, ITAR and CMMC Level 2 standards.

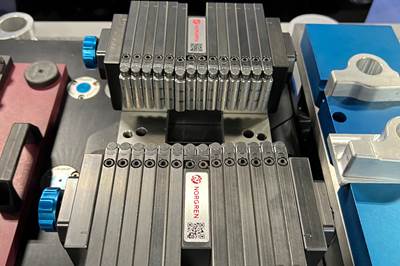

Read MoreNikon Metrology's Automation Software Connects the Shopfloor

The Inspect-X Automation OPC UA Interface software integrate third-party industrial, automation and control equipment more easily.

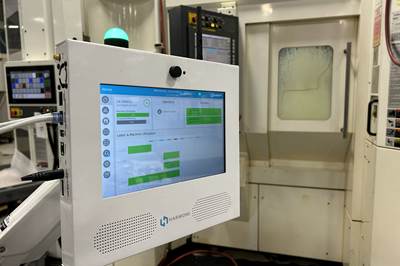

Read MoreFactoryWiz Monitoring System Reduces Operator Errors

Eastec 2023: FactoryWiz provides real-time monitoring and data analysis to give manufacturers insight into the production process and help them make informed decisions.

Read MoreCan Connecting ERP to Machine Tool Monitoring Address the Workforce Challenge?

It can if RFID tags are added. Here is how this startup sees a local Internet of Things aiding CNC machine shops.

Read MoreShop Moves to Aerospace Machining With Help From ERP

Coastal Machine is an oil and gas shop that pivoted to aerospace manufacturing with the help of an ERP system that made the certification process simple.

Read MoreWhen Handing Down the Family Machine Shop is as Complex as a Swiss-Turned Part

The transition into Swiss-type machining at Deking Screw Products required more than just a shift in production operations. It required a new mindset and a new way of running the family-owned business. Hardest of all, it required that one generation let go, and allow a new one to step in.

Read More