-

SPONSORED

-

SPONSORED

-

-

Holemaking

Video: Setting Boring Bar Offset On A Swiss-Type

This video clip from a MasterTask Training instructional course describes how to set the X-axis geometry offset for a boring bar on a Tsugami Swiss-type lathe.

WatchDrill Combines Modular, Solid Carbide Characteristics

Widia’s Victory Top Drill M1 modular drill, part of the company’s Victory platform of advanced milling, turning and hole making tools, is said to combine the economic benefits of modular drilling systems with the machining performance and hole quality of solid carbide tools.Available over a standard diameter range of 0.3150" to 0.8264" (8 to 20.99 mm) and at length-to-diameter ratios of 3×D and 5×D, drill bodies are available in either flanged-shank (metric) or round-shank (inch) configurations.

Read MoreThe Value Of Indexable-Insert Center Drills

This indexable-insert center drill, said to be an industry first, combines the drilling performance advantages of solid carbide with the positioning repeatability and quick-change benefits common to indexable-insert tooling.

Read MoreCKN Modular System For Large Boring

BIG Kaiser Precision Tooling’s CKN modular connection utilizes both steel and lightweight aluminum components.

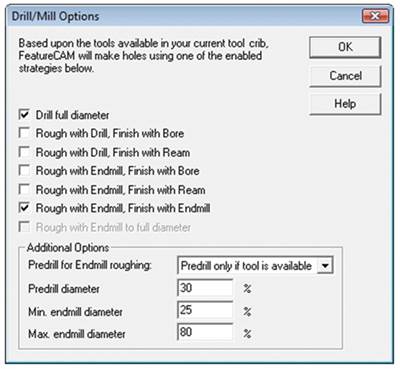

Read MoreUse The Tools That Are Available

Typically, creating holes isn’t a daunting task. However, programming, machine set up and cycle times can be prolonged when a part has numerous hole diameters. A new feature-based CAM strategy automatically determines how best to combine drilling and milling to create the holes using only the tools already loaded in a machine.

Read MoreMultifunctional Table-Type Boring, Milling Machines

The Speedmat 2, 3 and 4 models comprise Pama’s multifunctional, table-type boring and milling machine range. The boring spindle is available in two different sizes, 130 or 160 mm, and table sizes range from 1,250 × 1,250 mm to 2,000 × 2,500 mm.

Read MoreAdvanced CNC Course Available Online

Expert Technical Training’s training program is designed to give CNC machinists the advanced knowledge and high speed machining skills that are necessary to compete in the modern global economy. For example, CNC 200: Advanced CNC Milling and Drilling, is a fully featured, college-level course designed to fill in the knowledge gaps often present due to the rapid technological advancements in CNC machining.

Read MoreDrilling Unit Designed For Aerospace Applications

The Pneucon Selfeeder family of portable pneumatic drilling units from Sugino is designed specifically for the aerospace industry to streamline drilling applications on large wing and fuselage assemblies. The air-powered units feature a TIR of less than 0.

Read MoreLive Lathe Tools For ID Machining

Eltool’s live tool modules combined with the company’s right angle heads are designed for internal machining of bores ranging to l" in diameter. Secondary ID milling, drilling, slotting and grooving operations can be integrated into turning operations to increase throughput, reduce handling and improve accuracy.

Read MoreDrill Sharpener Helps Shop Hone Competitive Edge

Bringing drill sharpening operations in-house saved both time and money at this Chicago-based manufacturer. However, the sharpener itself, Darex’s XPS-16, provided additional benefits—with high accuracy and consistent results, the machine helped the company maintain precision and quality.

Read More