-

SPONSORED

-

SPONSORED

-

-

Metalworking Fluids

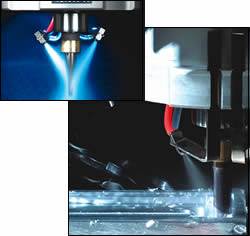

Alcohol-Based Coolant Offers Environmentally Friendly Machining

This micro-volume coolant delivery system uses ethanol as the cooling medium for non-ferrous workpieces. The ethanol evaporates after it cools the cutting tool, so no residue is left behind on machined workpieces.

Read MoreEffective Filtration Adds Machining Hours

Sussek Machine says its expertise extends beyond what one might expect of a traditional job shop. Off-highway equipment OEMs comprise a large portion of the shop’s clientele, as the company machines steering arms, knuckles, shifter forks and other cast iron components.

Read MoreA New Approach To Critical Fluid Maintenance

Today, viscosity can be measured precisely by a sensor device that is immersed directly under a stream of fluid or mounted in the fluid tank or pipeline. In simplified terms, the sensor uses sound waves that lose energy when emitted along surfaces of a quartz crystal in contact with the fluid.

Read MoreSeparator Solves Tramp Oil Dilemma

Debco Machine, Inc. (Natick, Massachusetts), a job shop specializing in precision components from aluminum, plastics and stainless steel, was faced with what it characterized as a particularly demanding requirement for tramp oil removal from the sump of a Matsuura 510 vertical machining center, a machine that is in nearly constant use. About 1 gallon per day of tramp oil enters the 100-gallon coolant sump of this machine.

Read More