-

SPONSORED

-

SPONSORED

-

-

Titanium Machining

Cabinet Oven Heat Treats Titanium

Grieve’s No. 965 is a 1,350°F, electrically-heated cabinet oven for heat treating titanium parts.

Read MoreOkuma Hosts 400 at Annual Technology Showcase

The event’s theme focused on the Industrial Internet of Things (IIoT).

Read MoreConstant-Chip-Load Machining Yields a Better Tool Path

With its in-house R&D program, this aerospace shop seeks to be a leader, not a follower, on the path to innovation in advanced manufacturing. Finding and embracing a better way to generate tool paths for highly efficient and economical metal removal is a prime example of the value of this program.

Read MoreThe Benefits of Horizontal Turning on a Mill-Turn Machine

A mill-turn machine that can rotate a large, bell-shaped workpiece in a horizontal orientation enabled this manufacturer to hit tight tolerance and cost targets. Minimizing non-value-added time and running lights out were also essential for success.

Read MoreA Practical Approach to Milling Titanium

When the right cutting tool, toolholder, cutter paths and machining parameters are applied intelligently, a shop may have more capability to mill titanium effectively than it recognizes.

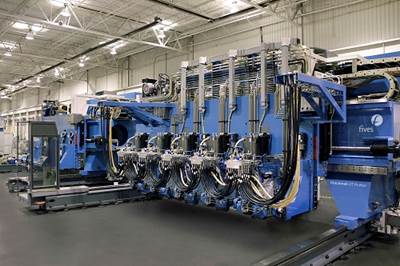

Read MoreProfiler Expected to Exceed 100 Cubic Inches per Minute in Titanium

Five-axis, five-spindle machine aims at reduced cost per piece for production of large aircraft components.

Read MoreVideo: Quiet Heavy Milling of Titanium

During test cutting with a new tool-and-toolholder combination for titanium, this video was shot to record the sound (or lack of sound) from a deep milling pass.

WatchEliminating Tool Pullout in Titanium Milling

Toolholder employs a secondary locking system to counter the high axial cutting forces encountered during the development of a tool for high-metal-removal-rate milling of titanium.

Read MoreWhat’s Best for Boring Titanium?

In a joint research effort, Kaiser Precision Tooling and Blaser Swisslube searched for a combination of metalworking fluid and indexable insert that show the best results when boring titanium. The results underscore the importance of controlling vibration, friction and heat.

Read MoreWhy Not Start With Waterjet?

In titanium, significant savings and process efficiency can result from the simple fact that abrasive waterjet cutting leaves the remaining stock intact.

Read More