-

SPONSORED

-

SPONSORED

Tooling

Vise Line Reduces Stress Under Load

Kurt’s pull-type HD690 vise line is available in standard and reverse jaw models, and in manual and hydraulic versions.

Read MoreCramming for Competitiveness

Low-profile clamps contribute to the high-density fixturing this shop needs to make the most of an equipment configuration that is increasingly renowned for reducing setups and keeping the spindle turning.

Read MorePallet-Change System Meets Demand for Automation

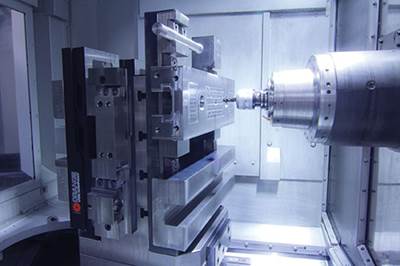

Hermle’s PW3000 pallet-change system is designed for use with the company’s five-axis C 60 machining center.

Read MorePrecision-Finish Boring Head for High-Speed Spindles

Big Kaiser’s EWN 04-7 series of precision-finish boring heads are designed for use on micro-milling machines with high-speed spindles such as HSK-E25, E32 or E40.

Read MoreMilling Chucks Reduce Run-Out

Rego-Fix’s millTite milling chucks are said to reduce run-out while increasing gripping force.

Read MoreMilling Inserts Reduce Cutting Forces

Iscar will display its Heli IQ Mill 390 milling inserts.

Read MoreHigh-Feed Quad Cutters for Milling

Ingersoll’s Hi-QuadF high-feed milling cutters are available with a 13-mm IC insert for 0.088" depth of cut or a 19-mm IC insert for 0.145" depth of cut.

Read MoreCollet Systems for CNC Lathes

The company will showcase its FlexC vulcanized collet systems, which are designed as a substitute for three-jaw chucks for use with CNC lathes.

Read MoreThread Mills Designed for Hardened Materials

Carmex offers two lines of multi-functional thread mills specifically designed to machine hardened materials ranging to 62 HRc.

Read MoreToolholder Avoids Tolerance Stacking

GenSwiss will feature its Ti-Loc SwissClamp slitting and milling toolholders designed to direct-mount to any ER16 collet holder using ER nuts.

Read More