-

SPONSORED

-

SPONSORED

Tooling

Lighted Workstop Verifies Part Location

Electrifying the work allows a light to indicate whether the setup is correct. The simple solution turned into a standard product for this shop.

Read MoreChipbreaking Inserts Improve ID Grooving

Iscar says its Cut-Grip inserts are suitable for ID grooving and feature an N-type chipformer for OD turning of “problematic” metals.

Read MoreER Collet Chuck System Offers Rigidity, Balance

With a runout accuracy of 0.00012" (3 microns) at 5×D, BIG Kaiser’s Mega ER Grip is designed to increase clamping force, concentricity, rigidity and balance at high spindle speeds.

Read MoreBallnose Cutters Increase Machining Performance

Ingersoll’s Finish-Ball Rush ballnose cutters are designed to increase machining performance.

Read MoreMini Toolholder Clamps Small Tools

The Tribos-Mini toolholder from Schunk directly clamps small tool shanks along the entire axis virtually eliminating collets, collet nuts and inconsistent cutting tool clamping.

Read MoreSolid Carbide Drills Improve Chip Flow, Evacuation

Seco Tools’ Feedmax -N solid carbide drills are designed for high-performance drilling in aluminum and nonferrous materials.

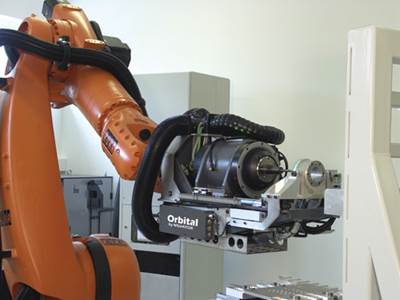

Read MoreEffective Hole Making Via Robotic Orbital Drilling

New technology may enable robotic drilling to be more commonplace in machine shops by overcoming the issue of limited robot rigidity.

Read MoreEnd Mills Improve Chamfering Performance

Extending the application capabilities of its tangential Sumomill inserts, Iscar offers end mills to perform chamfering, countersinking and face milling operations.

Read MoreMake Maximum Use of the Magazine

This shop streamlined its selection of cutting tools to machine a number of parts on a pallet system. Cutting down on cutters delivered other benefits as well.

Read MoreThe In-House Advantage

A shop that introduced its own product realizes the advantages of designing and machining a part under the same roof.

Read More