-

SPONSORED

-

SPONSORED

Tooling

New Tool, New Strategy Allow Five Times Faster Roughing

This shop realized a tool designed for fast feeds and shallow cutting depths could reduce the roughing cycle time of a large shipyard component from 20 to 4 minutes.

Read MoreShop Enjoys Five-Axis Benefits Without The Cost

Integrating Lyndex-Nikken rotary tables into three-axis Mori Seiki VMCs provided this shop with five-axis capability at a fraction of the cost of a new five-axis machine.

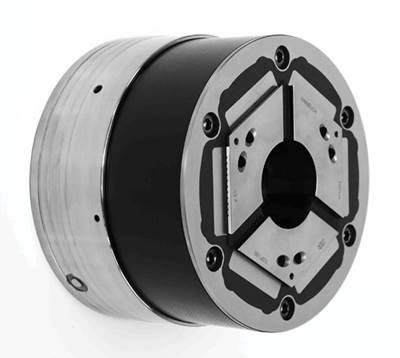

Read More“Intelligent” Chuck Regulates Clamping Force

Hainbuch is working to develop an “intelligent” chuck that monitors actual clamping forces on the workpiece and triggers necessary corrections automatically.

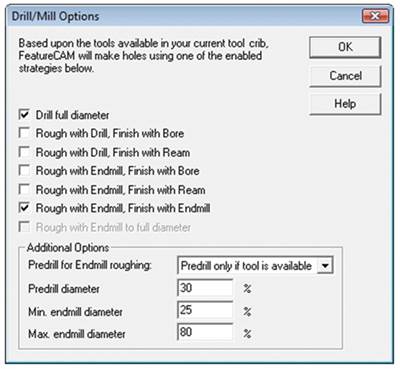

Read MoreUse The Tools That Are Available

Typically, creating holes isn’t a daunting task. However, programming, machine set up and cycle times can be prolonged when a part has numerous hole diameters. A new feature-based CAM strategy automatically determines how best to combine drilling and milling to create the holes using only the tools already loaded in a machine.

Read MoreMax-Flute Solid Carbide End Mill

(Sponsored Content) MAG’s CYCLO CUT cutting tool line introduces the Max-Flute solid carbide end mill. The Max-Flute technology delivers a step-change in machining of a broad spectrum of jet engine components in both titanium and nickel alloys. MAG’s Max-Flute was also selected the winner of the prestigious 2009 Sir Henry Royce Awards for Technical Innovation.

Read MoreNew Generation Of Steel Turning Grades

Sumitomo’s next generation of P20 and P30 coated carbide turning grades include the AC820P, which is designed for general-purpose turning of steels and stainless steels and the AC830P, which is designed for interrupted cuts and roughing. The Super FF coating provides wear and breakage resistance while increasing tool life.

Read MoreMultifunctional Table-Type Boring, Milling Machines

The Speedmat 2, 3 and 4 models comprise Pama’s multifunctional, table-type boring and milling machine range. The boring spindle is available in two different sizes, 130 or 160 mm, and table sizes range from 1,250 × 1,250 mm to 2,000 × 2,500 mm.

Read MoreAdvanced CNC Course Available Online

Expert Technical Training’s training program is designed to give CNC machinists the advanced knowledge and high speed machining skills that are necessary to compete in the modern global economy. For example, CNC 200: Advanced CNC Milling and Drilling, is a fully featured, college-level course designed to fill in the knowledge gaps often present due to the rapid technological advancements in CNC machining.

Read MoreDiamond Tool Features Self-Sharpening Edge

Brush Research Manufacturing’s diamond flex-hones are designed for deburring, edge blending and surface finishing in hard materials such as carbide, ceramic and aerospace steel alloys. The tools are engineered using resin-bond diamond crystals with high friability, a characteristic that makes edges self-sharpening.

Read MoreDrilling Unit Designed For Aerospace Applications

The Pneucon Selfeeder family of portable pneumatic drilling units from Sugino is designed specifically for the aerospace industry to streamline drilling applications on large wing and fuselage assemblies. The air-powered units feature a TIR of less than 0.

Read More